Activities Such As Purchasing Raw Materials Are Considered Activities.

Breaking News Today

Mar 25, 2025 · 6 min read

Table of Contents

Purchasing Raw Materials: A Deep Dive into Procurement Activities

Purchasing raw materials is far more than simply placing an order; it's a complex process encompassing numerous activities crucial to a company's success. This intricate dance of sourcing, negotiating, and managing materials directly impacts production efficiency, profitability, and ultimately, a company's bottom line. This comprehensive guide delves into the multifaceted world of purchasing raw materials, examining each activity with detail and offering strategies for optimization.

The Scope of Raw Material Procurement

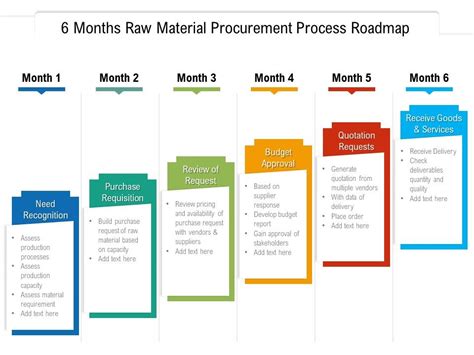

Before diving into the specific activities, it's crucial to understand the broad scope of raw material procurement. It's not merely a transactional process; it's a strategic function that significantly influences a company's competitive advantage. Effective procurement ensures the right materials are available at the right time, in the right quantity, and at the right price. This involves anticipating future needs, managing supplier relationships, and continuously optimizing the entire process for maximum efficiency and cost-effectiveness. The activities involved can be broadly classified into:

1. Planning and Forecasting: The Foundation of Procurement

Accurate forecasting is the bedrock of efficient raw material procurement. This involves analyzing historical data, market trends, sales forecasts, and production schedules to predict future demand. Sophisticated forecasting techniques, incorporating statistical modeling and machine learning, are becoming increasingly common to minimize inventory holding costs and avoid stockouts. Effective forecasting minimizes waste, reduces lead times, and improves overall operational efficiency.

Key Activities within Planning & Forecasting:

- Demand Forecasting: Utilizing historical sales data, market research, and predictive analytics to estimate future demand for finished goods and, consequently, raw materials.

- Inventory Management: Maintaining optimal inventory levels to balance supply and demand, minimizing storage costs while avoiding stockouts. Techniques like Just-In-Time (JIT) inventory management play a critical role.

- Supply Chain Risk Assessment: Identifying potential disruptions in the supply chain, such as natural disasters, geopolitical instability, or supplier failures, and developing contingency plans to mitigate risks.

2. Sourcing and Supplier Selection: Finding the Right Partners

Sourcing involves identifying and selecting suppliers who can consistently provide the necessary raw materials meeting quality standards and delivery requirements. This is a strategic process that goes beyond simply finding the cheapest supplier; it involves evaluating factors such as reliability, financial stability, ethical practices, and technological capabilities.

Key Activities within Sourcing & Supplier Selection:

- Supplier Identification: Researching and identifying potential suppliers through industry directories, online platforms, trade shows, and networking.

- Supplier Evaluation: Assessing suppliers based on criteria such as price, quality, delivery performance, financial stability, and ethical practices. This often involves thorough due diligence and audits.

- Negotiation and Contract Management: Negotiating favorable terms and conditions with suppliers, including pricing, payment terms, and delivery schedules. This requires strong negotiation skills and a deep understanding of market dynamics.

- Supplier Relationship Management (SRM): Building strong, collaborative relationships with key suppliers to ensure consistent supply and foster innovation.

3. Procurement Execution: Ordering and Receiving

Once suppliers are selected, the procurement execution phase begins. This involves placing orders, tracking shipments, receiving and inspecting materials, and managing any discrepancies or issues. Efficient execution minimizes delays, prevents errors, and ensures timely receipt of high-quality materials.

Key Activities within Procurement Execution:

- Order Placement: Submitting purchase orders to selected suppliers, specifying quantities, quality requirements, and delivery schedules. This often involves using electronic procurement systems for efficiency and traceability.

- Shipment Tracking: Monitoring the movement of materials from the supplier to the manufacturing facility, ensuring timely delivery.

- Goods Receipt and Inspection: Receiving and inspecting incoming materials to ensure they meet specifications and quality standards. This may involve quality control testing and documentation.

- Invoice Processing and Payment: Processing supplier invoices and making timely payments, adhering to agreed-upon payment terms.

4. Post-Procurement Activities: Analysis and Improvement

The procurement process doesn't end with receiving the materials. Continuous monitoring, analysis, and improvement are essential to optimize efficiency and reduce costs. This involves tracking key performance indicators (KPIs), identifying areas for improvement, and implementing corrective actions.

Key Activities within Post-Procurement Analysis:

- Performance Measurement: Tracking key KPIs such as on-time delivery, quality defects, and total cost of ownership to assess the performance of the procurement process.

- Spend Analysis: Analyzing procurement spending to identify areas for cost reduction and optimization.

- Process Improvement: Continuously evaluating and improving the procurement process to enhance efficiency, reduce costs, and improve supplier relationships. This might involve implementing new technologies or streamlining workflows.

Technological Advancements in Raw Material Procurement

Technology is revolutionizing raw material procurement, offering significant opportunities for improvement. Several key technologies are transforming how companies manage their supply chains:

- Enterprise Resource Planning (ERP) Systems: Integrated systems that manage all aspects of a company's operations, including procurement, inventory management, and accounting.

- Supply Chain Management (SCM) Software: Specialized software solutions that help companies optimize their supply chains, improving visibility, collaboration, and efficiency.

- Electronic Procurement (e-procurement) Systems: Online platforms that automate the purchasing process, streamlining ordering, tracking, and invoice processing.

- Blockchain Technology: Offers enhanced transparency and traceability throughout the supply chain, increasing trust and accountability.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can improve forecasting accuracy, optimize supplier selection, and automate various procurement tasks.

Optimizing Raw Material Procurement: Strategies for Success

Optimizing raw material procurement requires a holistic approach encompassing all aspects of the process. Here are some key strategies to enhance efficiency and reduce costs:

- Strategic Sourcing: Develop a long-term sourcing strategy that considers factors beyond price, such as supplier reliability, quality, and innovation.

- Supplier Relationship Management (SRM): Build strong, collaborative relationships with key suppliers to ensure consistent supply and foster innovation.

- Inventory Optimization: Implement inventory management techniques, such as Just-in-Time (JIT) inventory, to minimize holding costs and avoid stockouts.

- Technology Adoption: Leverage technology to automate tasks, improve visibility, and enhance decision-making.

- Continuous Improvement: Regularly evaluate and improve the procurement process to identify and address inefficiencies.

- Risk Management: Develop strategies to mitigate potential risks in the supply chain, such as disruptions due to natural disasters or geopolitical instability.

- Ethical Sourcing: Prioritize ethical sourcing practices, ensuring that suppliers adhere to fair labor standards and environmental regulations.

Conclusion: The Strategic Importance of Raw Material Procurement

Effective raw material procurement is a cornerstone of successful business operations. It's a strategic function that impacts profitability, operational efficiency, and a company's overall competitive advantage. By understanding the complexities of the procurement process, implementing best practices, and leveraging technological advancements, companies can significantly optimize their supply chains, reduce costs, and enhance their overall performance. The continuous pursuit of improvement and adaptation to changing market dynamics is key to maintaining a robust and resilient procurement function. The activities involved are not merely transactional; they are integral to the success of any business that relies on external resources for its operations. Through careful planning, diligent execution, and strategic analysis, businesses can unlock significant value from their raw material procurement processes.

Latest Posts

Latest Posts

-

Ustedes Darle Beso Recien Casado

Mar 28, 2025

-

Unit 5 Trigonometry Unit Test A Answers

Mar 28, 2025

-

You Should Increase Your Following Distance When You Are

Mar 28, 2025

-

Ati Dosage Calculation And Safe Medication Administration

Mar 28, 2025

-

Provider Networks May Be Accessed Through What Methods

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about Activities Such As Purchasing Raw Materials Are Considered Activities. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.