Approximately 75 Percent Of Struck By Fatalities Involve

Breaking News Today

Mar 21, 2025 · 6 min read

Table of Contents

Approximately 75 Percent of Struck-by Fatalities Involve: A Comprehensive Look at Workplace Safety

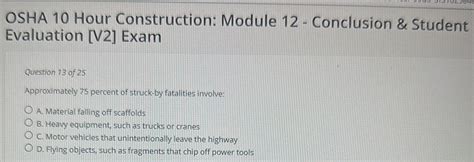

The stark reality is that a significant portion of workplace fatalities involve workers being struck by objects. While the exact percentage fluctuates slightly depending on the source and year, the statistic consistently hovers around 75%. This alarming figure underscores the critical need for robust safety protocols and a profound understanding of the contributing factors to these tragic incidents. This article delves deep into the causes behind this high percentage, explores preventative measures, and highlights the importance of a comprehensive safety culture.

The Leading Culprits: What Causes Struck-By Fatalities?

The 75% statistic isn't just a number; it represents real people, families, and communities impacted by preventable workplace accidents. To understand how to reduce this number, we must dissect the primary causes. These fall into several broad categories:

1. Falling Objects: A Constant Threat

A significant portion of struck-by fatalities involves falling objects. This can range from small tools and debris to large pieces of equipment or even entire structures. Construction sites are particularly vulnerable, with workers often exposed to potential hazards from above. Other industries, such as manufacturing and warehousing, also face risks from falling materials during handling and storage. The severity of injuries depends on the weight, speed, and point of impact of the falling object.

Contributing Factors to Falling Objects:

- Inadequate material handling practices: Improper stacking, securing, and lifting techniques are common causes.

- Lack of proper personal protective equipment (PPE): Hard hats are crucial, but their effectiveness diminishes without proper training and enforcement of usage.

- Insufficient safety training: Workers must be thoroughly trained on safe handling procedures and the identification of potential hazards.

- Poor site management: Cluttered work areas and lack of designated safe zones increase the risk of falling objects.

- Inadequate or damaged equipment: Faulty cranes, hoists, or scaffolding can lead to catastrophic failures.

2. Mobile Equipment: A Powerful Peril

Mobile equipment, including forklifts, cranes, excavators, and vehicles, poses a significant threat. These machines, while essential for many industries, can cause severe injuries or fatalities if not operated safely. Workers can be struck by the equipment itself or by materials being moved by the equipment.

Contributing Factors to Mobile Equipment Accidents:

- Blind spots and visibility issues: Operators need adequate training on maneuvering safely and awareness of pedestrian traffic.

- Unsafe operating procedures: Speeding, improper loading, and failure to follow safety protocols significantly increase the risk.

- Lack of communication and signaling: Clear communication systems are crucial to prevent collisions between equipment and pedestrians.

- Insufficient maintenance: Malfunctioning equipment increases the likelihood of accidents.

- Inadequate training and licensing: Operators need proper training and licensing before operating heavy machinery.

3. Flying Objects: An Unexpected Danger

Flying objects, such as projectiles from machinery, fragments from explosions, or debris from impacts, can be equally deadly. The unpredictable nature of these incidents makes prevention particularly challenging.

Contributing Factors to Flying Object Accidents:

- Lack of machine guarding: Adequate safeguards are critical to prevent projectiles from escaping machinery.

- Inadequate maintenance of equipment: Regular inspections and maintenance can prevent unexpected failures leading to flying objects.

- Improper use of tools and equipment: Using tools or equipment incorrectly can generate dangerous projectiles.

- Lack of proper safety procedures during demolition or explosive operations: Strict protocols are essential during these high-risk activities.

4. Struck by Vehicles: A Common Occurrence

Being struck by vehicles, including cars, trucks, and other motorized equipment within the workplace, contributes significantly to struck-by fatalities. This is prevalent in areas with significant pedestrian and vehicular traffic.

Contributing Factors to Vehicle-Related Accidents:

- Inadequate traffic control: Clearly marked pedestrian walkways, speed limits, and traffic signals are crucial.

- Lack of awareness: Both drivers and pedestrians need to be alert and aware of their surroundings.

- Poor visibility: Lighting, signage, and proper use of high-visibility clothing can improve visibility.

- Distracted driving or pedestrian behavior: Cell phone use and other distractions can lead to accidents.

Implementing Preventative Measures: A Multifaceted Approach

Reducing the alarming 75% statistic requires a comprehensive and multi-layered approach to workplace safety. This necessitates a shift towards a proactive safety culture rather than a reactive one.

1. Robust Safety Training: The Foundation of Prevention

Comprehensive safety training is paramount. This extends beyond simple inductions and must include:

- Hazard identification: Training workers to identify potential hazards is crucial for proactive risk mitigation.

- Safe work procedures: Clearly defined procedures for all tasks reduce the probability of errors.

- Emergency response planning: Workers should know how to respond to accidents and emergencies effectively.

- Use of PPE: Proper training on the selection, use, and maintenance of PPE is essential.

- Regular refresher training: Keeping skills sharp through periodic refresher courses is critical.

2. Engineering Controls: Designing Safety into the Workplace

Engineering controls involve implementing physical changes to the work environment to minimize hazards. Examples include:

- Improved machine guarding: Ensuring machines are adequately guarded to prevent projectiles.

- Enhanced material handling systems: Using better lifting equipment and storage solutions.

- Improved site layout: Optimizing the work area to reduce congestion and potential collisions.

- Installation of barriers and guards: Physical barriers can separate pedestrians from moving equipment or potential falling objects.

- Improved lighting and visibility: Adequate lighting can significantly reduce accidents.

3. Administrative Controls: Implementing Safe Work Practices

Administrative controls involve establishing clear policies and procedures to govern workplace safety. These include:

- Strict enforcement of safety rules: Consistent enforcement is critical to maintain a safe working environment.

- Regular safety inspections: Regular inspections identify potential hazards before accidents occur.

- Effective communication channels: Open communication allows workers to report hazards and concerns without fear of retribution.

- Incident investigation and analysis: Thorough investigation of incidents helps identify root causes and implement preventive measures.

- Development of safety manuals and procedures: Clear and concise safety manuals provide workers with the necessary information to work safely.

4. Personal Protective Equipment (PPE): The Last Line of Defense

While PPE is crucial, it should be considered a final line of defense, not a replacement for proper engineering and administrative controls. The proper selection, use, and maintenance of PPE are essential. This includes:

- Hard hats: Essential protection against falling objects.

- Safety glasses or goggles: Protecting eyes from flying debris.

- High-visibility clothing: Improving visibility in areas with moving equipment.

- Safety footwear: Protecting feet from falling objects and heavy equipment.

- Hearing protection: Protecting ears from loud noises generated by machinery.

The Importance of a Proactive Safety Culture

Beyond specific measures, cultivating a strong safety culture is paramount. This involves:

- Leadership commitment: Visible and unwavering commitment from leadership is crucial.

- Worker involvement: Empowering workers to identify and report hazards.

- Open communication: Creating a culture of open communication and feedback.

- Continuous improvement: Regularly reviewing and updating safety procedures.

- Celebrating successes: Recognizing and rewarding safe work practices.

Conclusion: A Collective Responsibility

The alarming statistic that approximately 75% of struck-by fatalities are preventable highlights a crucial need for a fundamental shift in workplace safety. This requires a collaborative effort involving employers, workers, and regulatory bodies. By implementing a comprehensive safety program encompassing robust training, engineering controls, administrative controls, proper PPE usage, and, most importantly, a proactive safety culture, we can significantly reduce the number of tragic struck-by fatalities and create safer workplaces for everyone. The investment in safety is not merely a cost; it's an investment in human lives and a responsible commitment to a safer future. Let's work together to drive this number down and make workplaces safer for all.

Latest Posts

Latest Posts

-

Which Of The Following Statements Are True Of Teams

Mar 27, 2025

-

A Group Of Biologists Is Studying The Competitive Relationships

Mar 27, 2025

-

The Keyword Tyranny In This Poster Is Primarily Used To

Mar 27, 2025

-

Irene Todavia No 1 Of 2 Lista Para Salir

Mar 27, 2025

-

A Bird Building Their Nest In A Tree

Mar 27, 2025

Related Post

Thank you for visiting our website which covers about Approximately 75 Percent Of Struck By Fatalities Involve . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.