Avoid __________ While Working In The Mechanics Laboratory.

Breaking News Today

Mar 14, 2025 · 6 min read

Table of Contents

Avoid These Hazards While Working in the Mechanics Laboratory

The mechanics laboratory is a dynamic environment brimming with opportunities for discovery and learning. However, it also presents inherent risks if safety protocols aren't meticulously followed. Ignoring these risks can lead to serious injuries, equipment damage, and disruptions to the learning process. This comprehensive guide details crucial safety precautions and hazards to avoid while working in a mechanics laboratory, ensuring a safe and productive experience for everyone.

Understanding the Mechanics Lab Environment: A Landscape of Potential Hazards

The mechanics lab is a unique space housing a wide array of equipment, tools, and materials, each posing its own specific dangers. These dangers can be broadly categorized into:

1. Mechanical Hazards: The Silent Threats

- Moving Machinery: Lathes, milling machines, drilling machines, and other power tools represent significant risks. Entanglement in moving parts, crushing injuries from rotating components, and projectiles from poorly maintained equipment are all possibilities. Always ensure machinery is properly guarded, and never operate equipment without proper training and authorization.

- Sharps and Cutting Tools: Knives, chisels, files, and various cutting instruments are commonplace in the lab. Cuts and punctures are common hazards. Always use appropriate safety gear, such as cut-resistant gloves, and dispose of sharp objects properly in designated containers. Never leave sharp tools unattended.

- Pinch Points: Areas where moving parts come close together or where objects can get trapped represent pinch points. Hands, fingers, and other body parts can be severely injured. Be mindful of these areas and maintain a safe distance from moving machinery.

- Flying Debris: Machining operations often produce flying debris such as metal chips, dust, and sparks. Eye injuries are a significant concern. Always wear appropriate eye protection, such as safety glasses or goggles, and ensure that machinery is properly shielded.

2. Electrical Hazards: The Invisible Dangers

- Exposed Wiring and Damaged Equipment: Faulty wiring, damaged insulation, and improperly grounded equipment can cause electric shock, potentially fatal. Never operate equipment with damaged cords or plugs. Report any damaged equipment immediately to the instructor or lab technician. Always ensure your hands are dry before handling electrical equipment.

- Overloading Circuits: Overloading electrical circuits can cause overheating, fires, and electrical shocks. Avoid plugging too many devices into a single outlet. Be aware of the circuit breaker capacity and adhere to the lab's guidelines on power usage.

- Static Electricity: Static electricity can build up in certain materials and cause sparks, potentially igniting flammable materials. Take appropriate precautions in areas with potentially flammable substances. Consider using anti-static mats or grounding straps.

3. Chemical Hazards: The Reactive Risks

- Exposure to Hazardous Substances: Many experiments may involve chemicals with varying degrees of toxicity, flammability, and reactivity. Always read the Safety Data Sheets (SDS) before handling any chemical. Wear appropriate personal protective equipment (PPE), including gloves, lab coats, and eye protection. Never mix chemicals without proper instruction.

- Inhalation of Fumes: Some chemical reactions produce hazardous fumes. Always work under a fume hood or in a well-ventilated area. Use respirators when necessary.

- Spills and Leaks: Chemical spills and leaks can be hazardous and require immediate cleanup. Follow established lab procedures for handling spills, including the use of appropriate absorbent materials and neutralizing agents.

4. Fire Hazards: A Constant Threat

- Flammable Materials: Many materials used in mechanics labs, such as solvents and lubricants, are flammable. Keep flammable materials away from ignition sources such as open flames, sparks, and hot surfaces. Store flammable materials in designated safety cabinets.

- Electrical Fires: Electrical faults can lead to fires. Inspect electrical equipment regularly for damage and report any problems immediately.

- Improper Waste Disposal: Improper disposal of flammable waste can lead to fires. Follow established lab procedures for waste disposal, ensuring that flammable materials are disposed of properly.

5. Ergonomic Hazards: The Long-Term Concerns

- Repetitive Strain Injuries: Performing repetitive tasks, such as tightening bolts or using hand tools for extended periods, can lead to repetitive strain injuries. Take regular breaks, use ergonomic tools and maintain proper posture. Avoid awkward postures and excessive force.

- Lifting Heavy Objects: Lifting heavy objects improperly can lead to back injuries. Use proper lifting techniques and seek assistance when necessary. Use mechanical lifting aids whenever possible.

- Prolonged Standing or Sitting: Prolonged periods of standing or sitting can lead to discomfort and fatigue. Take regular breaks and vary your posture.

Essential Safety Procedures to Adhere To in the Mechanics Laboratory

Following these procedures is paramount to minimizing risks within the lab environment:

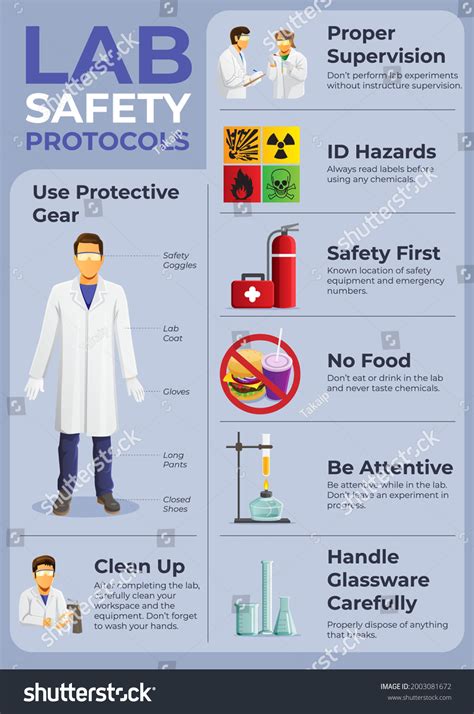

1. Personal Protective Equipment (PPE): Your First Line of Defense

- Eye Protection: Always wear safety glasses or goggles, regardless of the task. This protects your eyes from flying debris, chemical splashes, and other hazards.

- Hearing Protection: Use earplugs or earmuffs when operating loud machinery.

- Hand Protection: Wear appropriate gloves to protect your hands from cuts, abrasions, chemical exposure, and burns.

- Respiratory Protection: Use respirators when working with chemicals that produce hazardous fumes or dust.

- Foot Protection: Wear closed-toe shoes to protect your feet from falling objects and spills.

- Lab Coats: Wear a lab coat to protect your clothing from spills and splashes.

2. Safe Handling of Equipment and Tools

- Proper Training: Never operate any equipment without proper training and authorization. Seek guidance from instructors or experienced personnel.

- Regular Inspection: Inspect all equipment and tools before use to ensure they are in good working order. Report any damaged or faulty equipment immediately.

- Lockout/Tagout Procedures: Follow lockout/tagout procedures when performing maintenance or repairs on equipment. This ensures that the equipment is completely de-energized and prevented from accidental operation.

- Safe Operating Procedures: Adhere to all safe operating procedures for each piece of equipment. This includes proper start-up, operation, and shutdown procedures.

3. Chemical Safety Protocols: Handling with Care

- SDS Review: Always review the Safety Data Sheet (SDS) for any chemical before handling it. The SDS provides information on the chemical's hazards, safe handling procedures, and emergency response measures.

- Proper Storage: Store chemicals properly according to their labeling and SDS instructions. Keep incompatible chemicals separated.

- Spill Response: Know and follow the established spill response procedures for various chemicals.

4. Waste Disposal: Responsible Management

- Segregation: Separate waste materials according to their type (hazardous, non-hazardous, recyclable). Follow established lab procedures for waste disposal.

- Proper Containers: Use appropriate containers for waste disposal. Never mix different types of waste.

- Labeling: Clearly label waste containers with the contents and any necessary warnings.

5. Emergency Procedures: Preparedness is Key

- Emergency Exits: Locate and familiarize yourself with all emergency exits.

- First Aid: Know the location of the first aid kit and be familiar with basic first aid procedures.

- Emergency Contacts: Know the emergency contact numbers for the lab, university, and local emergency services.

- Emergency Showers and Eye Wash Stations: Know the location and operation of emergency showers and eye wash stations.

Beyond the Basics: Cultivating a Culture of Safety

Safety in the mechanics laboratory is not just about following rules; it's about cultivating a culture of safety awareness and responsibility. This means:

- Active Observation: Pay attention to your surroundings and be aware of potential hazards.

- Proactive Reporting: Report any unsafe conditions or practices to the instructor or lab technician immediately.

- Continuous Learning: Stay updated on safety procedures and best practices.

- Teamwork: Work collaboratively with fellow students and lab personnel to maintain a safe environment.

By diligently following these guidelines and fostering a culture of safety, you can significantly reduce the risk of accidents and injuries in the mechanics laboratory. Remember, a safe and productive laboratory environment is a shared responsibility, and your commitment to safety protects not only yourself but also your colleagues and the overall learning environment. Safety is not just a rule; it's a responsibility and a commitment.

Latest Posts

Latest Posts

-

What Norman Saw In Minneapolis And How Affected Him

Mar 14, 2025

-

Lord Of The Flies Chapter 1 Summary

Mar 14, 2025

-

If You Suspect Information Has Been Improperly Or Unnecessarily Classified

Mar 14, 2025

-

Identify The Components Contained In Each Of The Following Lipids

Mar 14, 2025

-

Who Designates Whether Information Is Classified And Its Classification Level

Mar 14, 2025

Related Post

Thank you for visiting our website which covers about Avoid __________ While Working In The Mechanics Laboratory. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.