Class V Issue And Turn In Procedures For Using Units

Breaking News Today

Mar 21, 2025 · 6 min read

Table of Contents

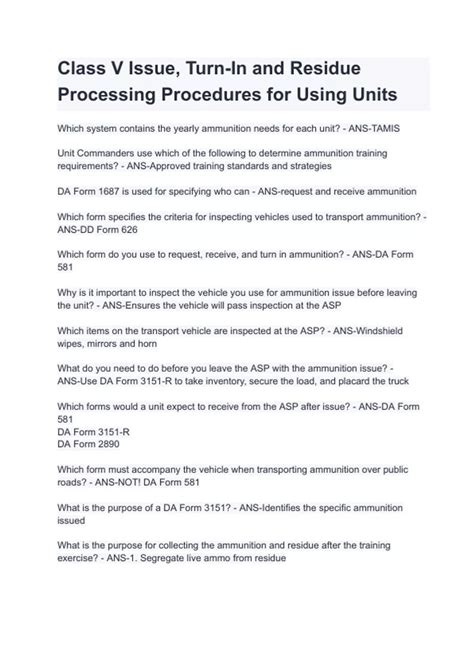

Class V Issues and Turn-In Procedures for Using Units

The effective management of Class V equipment (material) is crucial for any organization, particularly those operating in challenging environments or with high-value assets. Class V encompasses a wide range of items, from expendable supplies to durable equipment, and establishing clear procedures for their use and return is essential for maintaining accountability, minimizing losses, and ensuring operational efficiency. This article provides a comprehensive guide to addressing Class V issues and implementing robust turn-in procedures.

Understanding Class V Material

Before delving into procedures, it's vital to clearly define Class V material. It typically includes items that are:

- Consumable: Used up or expended during operation, such as ammunition, fuel, cleaning supplies, or lubricants.

- Expendable: Items with a limited lifespan or those subject to wear and tear that necessitate replacement after a certain period or usage, such as batteries, filters, or small tools.

- Durable: Items designed for repeated use and often have a longer lifespan, potentially requiring maintenance, but not necessarily replacement after each use. Examples include hand tools, protective gear, and some specialized equipment.

The classification can vary slightly depending on the organization, but the core principle remains: Class V materials are those that require careful tracking and management due to their consumption or potential depletion.

Common Class V Issues

Effective management requires anticipating and addressing potential issues. Common problems encountered with Class V material include:

1. Loss or Misplacement:

This is arguably the most prevalent issue. Poor inventory control, inadequate storage, and a lack of accountability can lead to significant losses of valuable resources.

2. Damage or Deterioration:

Improper handling, storage, or maintenance can damage or render Class V material unusable. This is particularly true for durable items. Exposure to extreme weather conditions or improper storage can shorten the lifespan of materials.

3. Theft:

Security vulnerabilities can result in theft, particularly with high-value or easily portable items. This is a serious concern demanding robust security measures.

4. Expiry or Obsolescence:

Consumable and expendable items often have expiry dates or can become obsolete. Failure to track expiry dates can lead to unusable material and wasted resources.

5. Inaccurate Inventory Records:

Poor record-keeping is the root cause of many Class V issues. Inaccurate data leads to poor resource allocation, supply chain problems, and difficulties in identifying losses or shortages.

6. Lack of Standardization:

Inconsistencies in how Class V items are categorized, identified, and tracked can create confusion and hinder efficient management. Standardization simplifies processes and improves accountability.

7. Inadequate Training:

Insufficient training for personnel on proper handling, storage, and reporting procedures can contribute to many of the issues mentioned above. Proper training is key to effective management.

Establishing Robust Turn-In Procedures

Implementing clear and consistent turn-in procedures is crucial for mitigating Class V issues. Key components of an effective system include:

1. Clear Identification and Labeling:

Each Class V item should be clearly identified with a unique identifier, possibly a serial number or barcode, for easy tracking throughout its lifecycle. Appropriate labeling ensures that items are easily identifiable during the turn-in process.

2. Designated Turn-In Points:

Establish clearly defined locations for returning Class V material. This simplifies the process and prevents items from being misplaced or lost. Well-marked and easily accessible turn-in points are essential.

3. Standardized Turn-In Forms:

Utilize standardized forms to document the return of Class V material. These forms should include fields for the item's identification number, quantity, condition, date of return, and the person returning the item. Digital forms can improve efficiency and data management.

4. Regular Inventory Checks:

Conduct regular inventory checks to verify the accuracy of records and identify any discrepancies. Regular audits help prevent significant losses from going unnoticed. Frequency should be determined based on the nature of the material and risk assessment.

5. Condition Reporting:

The turn-in process must include a thorough assessment of the item's condition. This involves documenting any damage, wear, or defects to accurately track the material's lifespan and identify potential maintenance needs. Photos can be a valuable addition to condition reports.

6. Accountability System:

Implement a system that holds personnel accountable for the Class V material they are assigned. This might include a signature-based system on turn-in forms, or a more advanced digital system tracking item usage and responsibility.

7. Disposal Procedures:

Establish clear procedures for disposing of unusable or expired Class V material. This should comply with environmental regulations and ensure responsible waste management. Proper disposal prevents potential hazards and environmental damage.

8. Training and Communication:

Regular training for personnel on Class V procedures is critical. This includes instruction on proper handling, storage, turn-in procedures, and the importance of accurate record-keeping. Clear communication ensures everyone understands their responsibilities.

9. Technology Integration:

Consider utilizing technology to improve efficiency and accuracy. Inventory management software, barcode scanners, and RFID tags can automate many aspects of the process and significantly reduce errors. Data analytics can reveal patterns and trends to inform better decision-making.

Addressing Specific Class V Issues Through Procedures

The turn-in procedures outlined above are designed to address the common issues discussed earlier. Let's look at how these procedures specifically help:

-

Loss or Misplacement: Clear identification, designated turn-in points, and regular inventory checks significantly reduce the likelihood of loss or misplacement. An efficient accountability system also aids in tracing missing items.

-

Damage or Deterioration: Detailed condition reporting upon turn-in helps identify damaged items early on. This allows for timely repairs or replacement, preventing further deterioration and minimizing losses.

-

Theft: A robust accountability system, along with secure storage facilities and potentially surveillance technology, can deter theft and facilitate the identification of perpetrators.

-

Expiry or Obsolescence: Tracking expiry dates and implementing regular inventory checks allow for the timely removal of outdated or expired materials, preventing waste and potential hazards.

-

Inaccurate Inventory Records: Standardized turn-in forms, regular inventory checks, and technology integration contribute to more accurate and reliable inventory records.

-

Lack of Standardization: Standardized procedures, forms, and labeling ensure consistency across the organization, eliminating confusion and improving efficiency.

-

Inadequate Training: Regular training sessions on proper procedures and the use of any technology involved will ensure that all personnel understand their responsibilities.

Continuous Improvement and Monitoring

Implementing a robust Class V management system is not a one-time effort. Continuous monitoring and improvement are essential to ensure its effectiveness. Regularly review the procedures, gather feedback from personnel, and analyze data to identify areas for improvement. This iterative approach ensures that the system adapts to changing needs and remains efficient and effective. Regularly review performance indicators such as loss rates, inventory accuracy, and compliance with procedures to identify areas needing attention.

Conclusion

Effective management of Class V material is critical for operational efficiency, cost control, and maintaining a secure environment. By implementing comprehensive turn-in procedures, organizations can minimize losses, improve accountability, and ensure that resources are used effectively. This requires a multi-faceted approach that encompasses clear identification, standardized processes, regular inventory checks, technology integration, and a commitment to continuous improvement. With a well-structured system, organizations can optimize their Class V management, leading to significant cost savings and enhanced operational effectiveness. The key is proactive planning, careful implementation, and consistent monitoring to achieve optimal results.

Latest Posts

Latest Posts

-

The Keyword Tyranny In This Poster Is Primarily Used To

Mar 27, 2025

-

Irene Todavia No 1 Of 2 Lista Para Salir

Mar 27, 2025

-

A Bird Building Their Nest In A Tree

Mar 27, 2025

-

Which Of The Following Is Not An Issue With Patching

Mar 27, 2025

-

What Is The Area Of The Regular Pentagon Below

Mar 27, 2025

Related Post

Thank you for visiting our website which covers about Class V Issue And Turn In Procedures For Using Units . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.