The Sensing Portion Of A Bi Metallic Stem Thermometer Is

Breaking News Today

Mar 19, 2025 · 6 min read

Table of Contents

The Sensing Portion of a Bimetallic Stem Thermometer: A Deep Dive

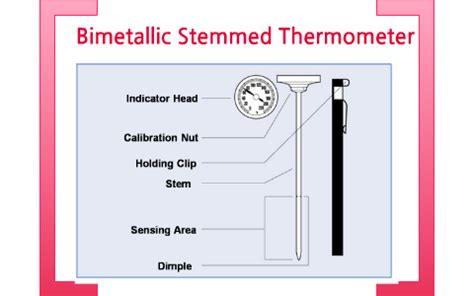

Bimetallic stem thermometers are ubiquitous in various industrial and domestic applications, offering a simple yet reliable method for temperature measurement. Understanding their operation, particularly the crucial role of the sensing portion, is key to appreciating their effectiveness and limitations. This article delves deep into the sensing element of a bimetallic stem thermometer, exploring its construction, function, and factors affecting its accuracy and longevity.

Understanding the Bimetallic Strip: The Heart of the Sensing Portion

The sensing portion of a bimetallic stem thermometer is fundamentally a bimetallic strip. This isn't just a single strip of metal; it's a cleverly engineered composite of two dissimilar metals, typically steel and brass, or invar and nickel. These metals are chosen for their differing coefficients of thermal expansion (CTE). This difference in CTE is the cornerstone of the thermometer's functionality.

The Significance of Differing CTEs

The coefficient of thermal expansion describes how much a material expands or contracts per degree change in temperature. Crucially, steel and brass (or invar and nickel) possess significantly different CTEs. When heat is applied, brass (or nickel) expands more than steel (or invar). This differential expansion is the driving force behind the thermometer's movement.

Construction and Coiling of the Bimetallic Strip

The two metals are bonded together through a precise process, ensuring a strong and consistent connection. This bonded strip is then carefully coiled into a tight spiral or helix. This coiling amplifies the minute movements caused by temperature changes, making them easily visible and measurable. The tighter the coil, the greater the amplification. However, excessively tight coiling can compromise the strip's strength and longevity.

The Role of the Pointer and Scale

The free end of the coiled bimetallic strip is connected to a pointer. As the temperature changes, the strip expands or contracts, causing the pointer to rotate along a calibrated scale. The scale is carefully marked to directly indicate the temperature. The accuracy of the temperature reading directly depends on the precision of both the strip's response and the scale's calibration.

Factors Affecting the Accuracy and Performance of the Sensing Portion

Several factors can influence the accuracy and overall performance of the bimetallic strip sensing portion:

1. Material Properties and Manufacturing Precision

The precise composition of the two metals, the bonding process, and the uniformity of the strip's thickness significantly affect the accuracy of the thermometer. Inconsistent bonding or variations in metal composition can lead to non-linear responses and inaccurate readings. High-quality manufacturing is paramount for reliable performance.

2. Temperature Range and Calibration

Bimetallic stem thermometers are designed for specific temperature ranges. Operating outside this range can lead to inaccurate readings or even damage to the sensing portion. Calibration is crucial to ensure accuracy within the designed range. Regular recalibration, especially after extended use or significant temperature fluctuations, is recommended for maintaining accuracy.

3. Environmental Factors

Environmental factors like vibration, shock, and exposure to corrosive substances can negatively impact the accuracy and longevity of the thermometer. Vibration can loosen the bonding between the metals, leading to inaccurate readings. Corrosive substances can degrade the metals, affecting the strip's response and overall durability.

4. Aging and Degradation

Over time, the bimetallic strip can experience material fatigue and degradation, leading to a drift in its response. This is particularly true for thermometers subjected to frequent temperature changes or extreme temperatures. Regular inspection and potential replacement are recommended for aging thermometers to maintain accuracy and safety.

5. Thermal Hysteresis

Bimetallic strips can exhibit a phenomenon called thermal hysteresis. This means the reading might slightly differ when the temperature is rising compared to when it is falling. This is due to the inherent properties of the metals and the manufacturing process. While usually small, this hysteresis can affect accuracy, particularly in applications requiring high precision.

Comparing Bimetallic Thermometers to Other Temperature Sensing Technologies

While bimetallic stem thermometers are widely used and appreciated for their simplicity and robustness, it's essential to compare them with other temperature sensing technologies to understand their strengths and weaknesses:

Advantages of Bimetallic Thermometers:

- Simplicity and Robustness: Their simple design makes them rugged and reliable, capable of withstanding harsh environments.

- Direct Reading: The direct visual reading eliminates the need for complex electronic circuitry.

- Cost-Effectiveness: Bimetallic thermometers are generally less expensive than other temperature sensing technologies.

- No External Power Source: They require no power source, making them suitable for applications where power is limited or unavailable.

Disadvantages of Bimetallic Thermometers:

- Lower Accuracy: Compared to other technologies like thermocouples or RTDs, bimetallic thermometers generally have lower accuracy.

- Limited Temperature Range: Their usable temperature range is limited by the properties of the bimetallic strip materials.

- Potential for Hysteresis: Thermal hysteresis can introduce minor inaccuracies in readings.

- Mechanical Wear: Over time, mechanical wear can affect the accuracy and longevity of the pointer and the bimetallic strip.

Alternatives to Bimetallic Thermometers:

- Thermocouples: These sensors offer high accuracy and a wide temperature range but require signal conditioning and a power source.

- Resistance Temperature Detectors (RTDs): RTDs are known for their high accuracy and stability, but they also need a power source and signal conditioning.

- Thermistors: Thermistors are compact and sensitive, but their temperature range is often more limited than bimetallic thermometers.

- Infrared Thermometers: These non-contact thermometers offer a convenient way to measure temperature but may be less accurate for certain applications.

Applications of Bimetallic Stem Thermometers

The simplicity, robustness, and cost-effectiveness of bimetallic stem thermometers make them suitable for a wide range of applications:

- Industrial Processes: Monitoring temperatures in ovens, kilns, and other industrial equipment.

- HVAC Systems: Measuring temperatures in heating, ventilation, and air conditioning systems.

- Food Processing: Monitoring temperatures during food preparation and storage.

- Automotive Applications: Measuring temperatures in engines and other automotive components.

- Laboratory Settings: Simple temperature monitoring in various laboratory experiments.

- Domestic Appliances: Temperature control in ovens, irons, and other household appliances.

Conclusion: Understanding the Sensing Portion for Optimal Usage

The sensing portion, the bimetallic strip, is the heart of a bimetallic stem thermometer. Understanding its construction, operation, and the factors affecting its performance is critical for correctly interpreting temperature readings and ensuring the thermometer's longevity. While they may not offer the same level of precision as other temperature sensors, their simplicity, robustness, and cost-effectiveness make them invaluable in numerous applications. Regular calibration and awareness of their limitations contribute to their effective and reliable use. Choosing the appropriate bimetallic thermometer for a specific application depends on the required accuracy, temperature range, and environmental conditions. With careful selection and maintenance, these simple devices continue to provide valuable temperature measurement in diverse settings.

Latest Posts

Latest Posts

-

Olfaction And Hearing Are Processed In The

Mar 19, 2025

-

The Term Pertaining To The Abdomen And Chest Is

Mar 19, 2025

-

Refers To A Seat In Congress Without An Incumbent

Mar 19, 2025

-

Study Of The Organization And Operation Of Governments

Mar 19, 2025

-

The Supreme Court Has Decided That The Death Penalty

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about The Sensing Portion Of A Bi Metallic Stem Thermometer Is . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.