What Causes Air Bubbles In A Model

Breaking News Today

Mar 26, 2025 · 6 min read

Table of Contents

What Causes Air Bubbles in a Model? A Comprehensive Guide

Air bubbles in a model, whether it's a 3D printed object, a resin cast, or a painted miniature, are a frustratingly common problem. They can significantly detract from the final product's appearance and even compromise its structural integrity. Understanding the root causes of these pesky bubbles is crucial for producing high-quality models. This comprehensive guide delves into the various reasons behind air bubble formation, offering practical solutions and preventative measures.

Understanding the Types of Air Bubbles

Before we explore the causes, it's important to understand the different types of air bubbles you might encounter:

1. Surface Bubbles:

These are bubbles trapped on the surface of your model. They're often the most visible and easiest to address. They typically appear as small, raised bumps or blemishes.

2. Internal Bubbles:

These are bubbles trapped within the material of your model. They can be more challenging to detect and remove, often appearing as voids or imperfections within the structure. Internal bubbles can weaken the model and potentially cause cracking.

3. Pinholes:

These are tiny, almost microscopic bubbles that often appear as small pits or imperfections on the surface. They are particularly common in resin casting and 3D printing.

Causes of Air Bubbles in Different Modeling Techniques

The causes of air bubbles vary depending on the specific modeling technique used. Let's examine the most common methods:

Air Bubbles in 3D Printing:

-

Filament Issues: Moisture in the filament is a primary culprit. Moisture absorbs into the filament, causing it to release gases during the printing process. This manifests as bubbles. Ensure your filament is properly stored in a dry, airtight container.

-

Insufficient Extrusion Temperature: A temperature that's too low can prevent the filament from melting completely, leading to incomplete bonding and trapping air bubbles. Refer to the manufacturer's recommendations for the optimal temperature for your filament type.

-

Printing Too Fast: Rushing the printing process prevents the molten filament from properly bonding and flowing smoothly. Reduce printing speeds to allow sufficient time for layer adhesion.

-

Incorrect Bed Adhesion: Poor bed adhesion can cause the first layers to lift, trapping air underneath. Ensure a properly leveled print bed and use an adhesion promoter if necessary.

-

Improper Cooling: Rapid cooling can trap air within the solidifying filament. Consider using slower cooling settings or a heated bed to encourage better layer adhesion.

-

Faulty Nozzle: A clogged or damaged nozzle can prevent the filament from extruding smoothly, resulting in inconsistencies and air bubbles. Regular nozzle maintenance is essential.

-

Draft Shielding: Even small air currents can interfere with the printing process. Draft shielding helps create a stable environment for optimal layer adhesion.

Air Bubbles in Resin Casting:

-

Improper Mixing: Insufficient mixing of resin and hardener leads to uneven curing and air bubble formation. Follow the manufacturer's instructions carefully for accurate mixing ratios and time.

-

Pouring Technique: Pouring the resin too quickly or forcefully can introduce air bubbles. Pour slowly and gently to minimize disturbance.

-

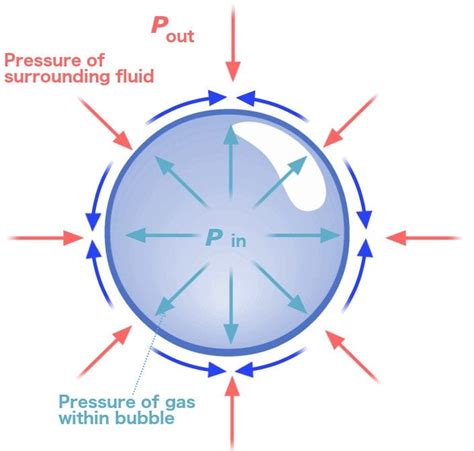

Vacuum Degassing: Air bubbles can be introduced during the pouring process. Before casting, consider degassing the resin under a vacuum to remove trapped air.

-

Mold Release Agent: Using an excessive amount of mold release agent can create a barrier that prevents proper resin flow, leading to trapped air. Use the recommended amount according to the manufacturer’s instructions.

-

Mold Imperfections: Any imperfections or gaps in your mold will trap air. Ensure your molds are clean, smooth, and free of any defects.

-

Temperature: Extreme temperatures during the curing process can affect the viscosity and flow of the resin, leading to bubble formation. Maintain a consistent and controlled temperature environment.

-

Curing Time: Insufficient curing time may leave the resin uncured, resulting in trapped gases and bubbles. Allow the resin to cure completely before demolding.

Air Bubbles in Painting and Modeling:

-

Thick Paint Coats: Applying thick coats of paint increases the chances of trapping air bubbles. Apply thin, even coats and allow each layer to dry thoroughly before applying the next.

-

Shaking the Paint: Vigorous shaking of paint can introduce air bubbles. Instead of shaking, gently stir or roll the paint container.

-

Using an Airbrush: Incorrect airbrush pressure or technique can lead to air bubbles in the paint application. Adjust the pressure and ensure the paint is properly thinned.

-

Poor Surface Preparation: Dust, debris, or grease on the model's surface can prevent the paint from adhering properly and may create pockets of trapped air. Always thoroughly clean and prime the surface.

Troubleshooting and Prevention Strategies:

Addressing air bubbles requires a multi-faceted approach that includes preventative measures and troubleshooting techniques. Here’s a breakdown:

General Prevention Strategies:

-

Maintain a Clean Workspace: A clean workspace free of dust and debris minimizes the risk of contaminants interfering with the modeling process.

-

Proper Material Storage: Store your materials correctly. This includes filaments in airtight containers and resins in a cool, dry place.

-

Slow and Steady: Whether it's pouring resin or applying paint, working slowly and deliberately helps to avoid introducing air bubbles.

-

Temperature Control: Maintain a consistent temperature for both materials and the surrounding environment.

-

Practice and Patience: Consistent practice and patience is paramount to refining your techniques and improving the final result.

Specific Troubleshooting Techniques:

-

For 3D Printing: Experiment with different temperatures, speeds, and bed adhesion methods. Consider using a heated bed and enclosure for a more controlled environment.

-

For Resin Casting: Degassing the resin under vacuum is a highly effective technique. Use a pressure pot for curing resin castings to prevent bubble formation.

-

For Painting: Apply thin coats of paint, stir gently rather than shaking, and use a suitable primer to ensure proper adhesion. Consider using an airbrush with appropriate settings.

-

Post-Processing Techniques: For minor surface bubbles, careful sanding or polishing can often remove them. For internal bubbles, post-processing is less effective, highlighting the importance of prevention.

Advanced Techniques for Air Bubble Prevention

For more advanced modelers, implementing some additional techniques can significantly reduce air bubble occurrences.

-

Pressure Pot for Resin Casting: A pressure pot applies external pressure during the curing process, effectively compressing any trapped air bubbles.

-

Vacuum Degassing: This technique involves placing the resin under a vacuum to remove dissolved air before pouring. It significantly reduces the number of bubbles formed.

-

Proper Mold Preparation: Ensuring your mold is perfectly clean, smooth, and free from imperfections is crucial to preventing air pockets. Consider using mold release agents sparingly.

-

Multi-Material Printing: In 3D printing, strategically combining materials can help reduce the impact of bubbles by creating a more robust and less prone to air entrapment structure.

-

Advanced 3D Printing Settings: Familiarize yourself with advanced printer settings, such as retraction settings and flow rates, that can help optimize the extrusion process and minimize bubble formation.

Conclusion:

Air bubbles in models are a common issue, but by understanding the root causes and implementing the preventive measures and troubleshooting techniques discussed in this article, you can drastically reduce their occurrence and significantly improve the quality of your work. Remember, consistent practice and attention to detail are key to achieving flawless results. By implementing these strategies, you'll be well on your way to producing high-quality models free from the frustration of air bubbles. Continuously experimenting with your process and refining your techniques will lead to significant improvements over time. So, keep practicing and enjoy creating beautiful, flawless models!

Latest Posts

Latest Posts

-

A Policyowner Can Receive An Immediate Payment

Mar 26, 2025

-

Which Statement Is Correct About Dental Implants

Mar 26, 2025

-

Match The Design Thinking Stage To Its Description

Mar 26, 2025

-

La Madre De Mi Madre Es Mi

Mar 26, 2025

-

Skills Module 3 0 Central Venous Access Devices Posttest

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about What Causes Air Bubbles In A Model . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.