4 Ways Physical Characteristics Of A Fiber Can Be Examined

Breaking News Today

Mar 19, 2025 · 8 min read

Table of Contents

4 Ways Physical Characteristics of a Fiber Can Be Examined

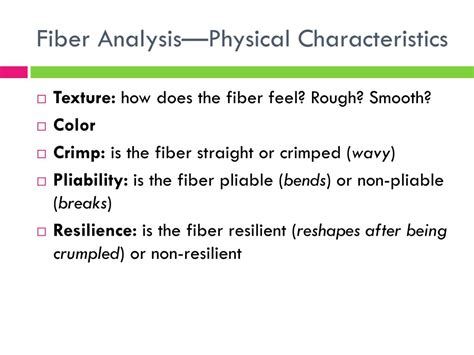

Fiber analysis plays a crucial role in various fields, including forensic science, textile manufacturing, and material science. Understanding the physical characteristics of fibers is essential for identification, comparison, and ultimately, solving mysteries or improving product quality. This article delves into four key methods for examining the physical characteristics of fibers, providing a detailed overview of each technique and its applications.

1. Microscopic Examination: The Foundation of Fiber Analysis

Microscopic examination forms the cornerstone of fiber analysis. It allows for the detailed observation of fiber morphology, revealing crucial information about its structure, shape, and surface characteristics. This non-destructive technique utilizes various microscopy types to provide comprehensive insights.

1.1. Stereo Microscopy: A Macroscopic View

Stereo microscopy, also known as stereoscopic microscopy, offers a three-dimensional view of the fiber, enabling the examination of its overall shape, size, and any surface irregularities. This low-magnification technique is particularly useful for initial assessments, allowing analysts to identify the fiber type broadly (e.g., natural or synthetic) and note distinguishing features such as twists, kinks, or surface damage. It's invaluable for sorting and classifying fibers before moving to higher magnification techniques.

Key features observed under stereo microscopy:

- Fiber length: Measuring the length of the fiber provides valuable information, particularly differentiating between staple fibers (short) and filament fibers (long).

- Fiber diameter: Determining the diameter helps in fiber classification and comparison. Variations in diameter can indicate different manufacturing processes or fiber types.

- Fiber shape: The overall shape—round, flat, trilobal, etc.—is a key identifier. Synthetic fibers often exhibit specific shapes determined by the extrusion process.

- Surface characteristics: Surface features such as longitudinal striations (parallel lines), scales (in natural fibers like wool), or delustering agents (in synthetic fibers) are easily observed. These features are crucial for differentiating fiber types.

1.2. Compound Microscopy: Delving into the Details

Compound microscopy provides significantly higher magnification than stereo microscopy, enabling a more detailed examination of the fiber's internal structure and finer surface features. This technique utilizes transmitted light, meaning light passes through the fiber, revealing its internal structure and any variations in refractive index.

Key features observed under compound microscopy:

- Cross-sectional shape: By observing a cross-section of the fiber, analysts can identify its shape (round, kidney-shaped, triangular, etc.), a critical characteristic for distinguishing synthetic fiber types.

- Internal structure: Internal structures such as the presence of core and sheath layers (in some synthetic fibers), or the medullary canal (in some natural fibers) can be observed, aiding in precise identification.

- Color and pigmentation: Compound microscopy allows for the detailed examination of fiber color and the presence of pigments. This is crucial for comparing fibers from different sources.

- Refractive index: Measuring the refractive index of the fiber, which is a measure of how light bends as it passes through the fiber, helps in identifying the fiber type. This measurement can be done using specialized techniques like Becke line observation.

1.3. Polarized Light Microscopy: Unveiling Crystalline Structure

Polarized light microscopy utilizes polarized light to reveal the crystalline structure of the fiber. This technique is particularly useful for distinguishing between different types of natural fibers (e.g., cotton, linen, silk) and for analyzing the orientation of crystalline regions within synthetic fibers. The interaction of polarized light with the fiber's crystalline structure results in characteristic birefringence patterns, which provide valuable information about fiber identity.

Key features observed under polarized light microscopy:

- Birefringence: The difference in refractive index along different axes of the fiber. This is a characteristic property of crystalline materials and differs significantly between fiber types.

- Extinction angle: The angle at which the fiber appears dark under crossed polarizers, providing information about the fiber's molecular orientation.

- Sign of elongation: This indicates whether the refractive index is higher along the fiber's length or its width. This property is useful in differentiating between various fiber types.

2. Chemical Analysis: Unveiling the Fiber's Composition

While microscopy focuses on the physical structure, chemical analysis delves into the fiber's chemical composition. This approach provides complementary information, often crucial for definitive fiber identification. Several techniques are employed, depending on the type of fiber and the information sought.

2.1. Burning Tests: A Simple Yet Informative Test

Burning tests are a relatively simple and rapid method for preliminary fiber classification. By observing how a fiber burns (rate of burning, odor produced, residue left), analysts can gain clues about its chemical composition. This method isn't definitive but serves as a quick screening tool.

Observations during burning tests:

- Rate of burning: Some fibers burn rapidly, while others burn slowly.

- Odor: The odor produced during burning can be characteristic of the fiber type (e.g., wool smells like burning hair, acetate smells like vinegar).

- Residue: The residue left after burning (ash, bead, etc.) provides additional information about the fiber's composition.

2.2. Solubility Tests: Dissolving Clues

Solubility tests examine a fiber's behavior in various solvents. Different fibers have different solubilities, allowing analysts to distinguish between them. This method involves immersing a fiber sample in different solvents and observing its reaction (dissolution, swelling, or no reaction).

Observations during solubility tests:

- Dissolution: Complete dissolution indicates the fiber is soluble in that particular solvent.

- Swelling: Swelling suggests the fiber is partially soluble or interacts with the solvent.

- No reaction: No change indicates the fiber is insoluble in that solvent.

2.3. Chromatography and Spectrometry: Advanced Chemical Profiling

Chromatography and spectrometry provide more precise chemical characterization of fibers. Techniques such as gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC) can identify the specific chemical components of a fiber, providing definitive identification and even tracing the source of the fiber. These techniques are particularly useful for analyzing synthetic fibers and identifying their polymer composition.

3. Mechanical Testing: Assessing Fiber Strength and Properties

Mechanical testing evaluates a fiber's physical strength and other mechanical properties. This information is critical in various applications, including textile manufacturing and material science. Various tests can be performed depending on the desired information.

3.1. Tensile Strength Testing: Measuring the Fiber's Resistance to Stretching

Tensile strength testing measures a fiber's resistance to breaking when subjected to tensile stress. This test provides information about the fiber's strength, elasticity, and elongation at break. The results are crucial for assessing the quality and durability of fibers used in textiles and other applications.

Key parameters measured:

- Tensile strength: The maximum force a fiber can withstand before breaking.

- Elongation at break: The extent to which a fiber can stretch before breaking.

- Modulus of elasticity: A measure of a fiber's stiffness or resistance to deformation.

3.2. Flexural Strength Testing: Evaluating Resistance to Bending

Flexural strength testing assesses a fiber's resistance to bending or flexing. This test is particularly important for fibers used in applications where bending is common, such as fabrics and composites. The test measures the force required to cause a fiber to break or fracture under bending stress.

Key parameters measured:

- Flexural strength: The maximum stress a fiber can withstand before breaking under bending.

- Flexural modulus: A measure of a fiber's stiffness or resistance to bending.

4. Thermal Analysis: Examining Fiber Behavior under Heat

Thermal analysis techniques examine the behavior of fibers when subjected to varying temperatures. These methods provide information about a fiber's thermal stability, melting point, and glass transition temperature.

4.1. Thermogravimetric Analysis (TGA): Monitoring Weight Changes with Temperature

TGA measures the weight changes of a fiber as a function of temperature. This technique is useful for determining a fiber's thermal stability, identifying decomposition points, and assessing the presence of volatile components.

Key information obtained:

- Thermal stability: The temperature range over which a fiber remains stable without significant weight loss.

- Decomposition temperature: The temperature at which a fiber starts to decompose.

- Weight loss profile: The pattern of weight loss as a function of temperature, providing information about the volatile components present.

4.2. Differential Scanning Calorimetry (DSC): Measuring Heat Flow Changes

DSC measures the heat flow into or out of a fiber as a function of temperature. This technique is particularly useful for determining a fiber's melting point, glass transition temperature, and crystallization behavior. The information obtained is crucial for understanding a fiber's thermal properties and behavior during processing.

Key information obtained:

- Melting point: The temperature at which a fiber melts.

- Glass transition temperature: The temperature at which a fiber transitions from a glassy state to a rubbery state.

- Crystallization temperature: The temperature at which a fiber crystallizes.

In conclusion, the physical characteristics of fibers can be examined using a variety of techniques, each providing valuable and complementary information. The selection of appropriate methods depends on the type of fiber, the purpose of the analysis, and the resources available. Combining microscopy, chemical analysis, mechanical testing, and thermal analysis enables a comprehensive understanding of fiber properties, which is crucial for identification, comparison, quality control, and forensic investigations. The continuous development and refinement of these analytical techniques ensure the accurate and detailed characterization of fibers across diverse applications.

Latest Posts

Latest Posts

-

You Are Called To The Bedside Of An Unresponsive 57

Mar 19, 2025

-

When Jackson Hears That His Neighbors House Has Been Robbed

Mar 19, 2025

-

Which Word Shares A Word Root With Remember

Mar 19, 2025

-

What Event Happened After The Qin Dynasty Collapsed

Mar 19, 2025

-

The Crossover Point Is That Production Quantity Where

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about 4 Ways Physical Characteristics Of A Fiber Can Be Examined . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.