A Is Placed On A Tank To Protect The Valves

Breaking News Today

Mar 27, 2025 · 5 min read

Table of Contents

Protecting Tank Valves: A Comprehensive Guide to Valve Protection and Safety

Protecting valves on tanks is crucial for safety, efficiency, and cost-effectiveness. Valves are critical components, controlling the flow of liquids, gases, or slurries within a tank. Damage to these valves can lead to leaks, spills, equipment failure, and potentially serious safety hazards. This comprehensive guide delves into the various methods and considerations for protecting tank valves, ensuring optimal operation and minimizing risks.

Why is Valve Protection Essential?

The importance of protecting tank valves cannot be overstated. Several factors contribute to this necessity:

Preventing Damage and Leaks:

- Physical Impact: Tanks are often located in environments where accidental impacts from forklifts, vehicles, or falling objects are possible. Unprotected valves are highly vulnerable to damage, potentially leading to leaks and spills.

- Corrosion: Exposure to harsh weather conditions, chemicals, or corrosive substances can degrade valves over time, causing weakening and ultimately failure.

- Vandalism: In some areas, vandalism can be a significant risk, with valves being deliberately damaged or tampered with.

- Erosion: The constant flow of liquids or gases can cause erosion of the valve components, reducing their lifespan and increasing the likelihood of failure.

Maintaining Operational Efficiency:

- Preventing Downtime: Damaged valves necessitate repairs or replacements, leading to costly downtime and production interruptions. Proactive protection measures minimize such disruptions.

- Ensuring Consistent Flow: Protected valves ensure consistent and reliable flow control, preventing fluctuations and operational inconsistencies.

- Reducing Maintenance Costs: Preventive protection measures help extend the lifespan of valves, reducing the frequency and cost of maintenance.

Enhancing Safety:

- Preventing Leaks and Spills: Leaks and spills can be hazardous, leading to environmental contamination, safety risks to personnel, and potential explosions depending on the contained substance.

- Protecting Personnel: Unprotected valves present a risk of injury to personnel who may accidentally come into contact with them. Proper protection minimizes such hazards.

- Compliance with Regulations: Many industries have strict regulations regarding the handling and protection of hazardous materials and equipment. Proper valve protection is essential for compliance.

Methods for Protecting Tank Valves

Several methods are available for protecting tank valves, ranging from simple to sophisticated, depending on the specific needs and risks involved.

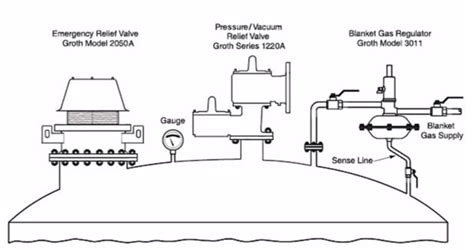

1. Protective Housings and Enclosures:

These are arguably the most common and effective method. They provide a physical barrier around the valve, shielding it from damage.

- Types: Housings come in various materials, sizes, and designs. They can be simple metal boxes or more complex, custom-engineered units.

- Material Selection: The material selection depends on the environmental conditions and the nature of the substance stored in the tank. Common materials include stainless steel, galvanized steel, and polymers.

- Design Considerations: Housings should allow for easy access to the valve for operation and maintenance while still providing adequate protection. Proper ventilation may also be required.

2. Valve Guards and Shields:

These offer a less encompassing form of protection compared to housings. They primarily protect against accidental impacts and physical damage.

- Types: Valve guards range from simple metal plates to more sophisticated designs incorporating shock absorption mechanisms.

- Material Selection: Similar considerations apply as with protective housings. The choice depends on the environment and potential threats.

- Installation: Installation is generally straightforward, requiring minimal modifications to the existing tank structure.

3. Lockout/Tagout (LOTO) Procedures:

While not a physical protective method, LOTO procedures are vital for safety. They ensure valves are properly secured and isolated during maintenance or repairs to prevent accidental operation and subsequent hazards.

- Purpose: Preventing unauthorized access and accidental operation during maintenance or repair.

- Implementation: Proper lockout procedures involve the use of locks and tags to visually indicate that the valve is isolated and should not be operated.

- Training: Personnel must receive thorough training on proper LOTO procedures to ensure effective implementation.

4. Insulation and Weather Protection:

Extreme temperatures and harsh weather conditions can damage valves. Insulation and weather protection help mitigate these risks.

- Insulation: Insulation helps maintain consistent temperatures around the valve, preventing damage from extreme heat or cold.

- Weather Protection: Covers, shelters, or other protective measures can shield valves from rain, snow, and other elements.

- Material Selection: Insulation and weather protection materials should be chosen based on the temperature range and environmental conditions.

5. Remote Operation and Monitoring:

Remote operation minimizes the need for direct interaction with the valve, reducing the risk of damage or injury.

- Benefits: Reduced personnel exposure to hazardous conditions.

- Implementation: Remote operation systems utilize various technologies, including pneumatic, hydraulic, or electrical actuators.

- Monitoring: Remote monitoring systems provide real-time data on valve operation, including pressure, temperature, and flow rate, enabling proactive maintenance.

Choosing the Right Protection Method

The selection of the most appropriate protection method depends on several factors:

- Type of Valve: Different valves have different vulnerabilities. The choice of protection method should consider the valve’s design and materials.

- Operating Conditions: Harsh environmental conditions (extreme temperatures, corrosive substances) demand more robust protective measures.

- Risk Assessment: A comprehensive risk assessment is crucial for determining the appropriate level of protection. This assessment should identify potential hazards and their likelihood.

- Budget: Different protection methods have varying costs. The choice must consider the budget and cost-benefit analysis.

- Maintenance Considerations: The chosen method should be easy to maintain and access for inspection and repair.

Beyond Physical Protection: Maintenance and Inspection

Even with the best protective measures, regular maintenance and inspection are essential.

- Regular Inspections: Frequent visual inspections should be conducted to check for signs of wear, corrosion, or damage.

- Preventative Maintenance: Scheduled maintenance tasks, such as lubrication and cleaning, help prolong the lifespan of valves and protective equipment.

- Documentation: Maintaining detailed records of inspections and maintenance activities is crucial for tracking the condition of valves and identifying potential issues.

Conclusion

Protecting tank valves is a multifaceted endeavor, encompassing physical protection, operational procedures, and consistent maintenance. By employing appropriate methods and adhering to safe practices, industries can significantly mitigate risks, enhance safety, improve efficiency, and ultimately reduce costs. A proactive approach to valve protection ensures the smooth, safe, and reliable operation of tanks and associated equipment. Remember, the cost of preventing damage far outweighs the cost of repairs and potential safety incidents. Invest in proper valve protection and safeguard your operations.

Latest Posts

Latest Posts

-

Which Best Describes An Overall Effect Of The Harlme Renaissance

Mar 30, 2025

-

Muhammad Ali Tried To Westernize Egypt By

Mar 30, 2025

-

A Non Food Contact Surface Must Be

Mar 30, 2025

-

Wanted A Just Right Government Crossword Answer Key

Mar 30, 2025

-

The Usual Starting Point For A Master Budget Is

Mar 30, 2025

Related Post

Thank you for visiting our website which covers about A Is Placed On A Tank To Protect The Valves . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.