How Is The Equivalent Length Of A Duct Determined

Breaking News Today

Mar 17, 2025 · 6 min read

Table of Contents

How is the Equivalent Length of a Duct Determined?

Determining the equivalent length of a duct is crucial in HVAC (Heating, Ventilation, and Air Conditioning) system design. It's a critical factor in accurately calculating pressure drop across the ductwork, ensuring proper airflow, and ultimately, the efficient and effective performance of the entire system. Understanding how equivalent length is determined requires a grasp of several key concepts, including friction losses, fittings, and the complexities of airflow within non-circular ducts. This comprehensive guide will delve into the intricacies of calculating equivalent length, providing a clear and practical understanding for HVAC professionals and enthusiasts alike.

Understanding Pressure Drop in Ductwork

Before diving into equivalent length calculations, it's essential to understand the concept of pressure drop in ductwork. Air moving through a duct experiences friction against the duct walls, leading to a reduction in pressure. This pressure drop is influenced by several factors, including:

- Duct Length: Longer ducts inherently cause more pressure drop due to increased frictional resistance.

- Duct Diameter/Shape: Smaller diameter ducts and non-circular shapes (e.g., rectangular ducts) create greater frictional resistance compared to larger diameter circular ducts. This is because of the increased surface area in contact with the air.

- Air Velocity: Higher air velocities result in increased pressure drop due to enhanced frictional forces.

- Air Density: Denser air exhibits higher frictional resistance, leading to a greater pressure drop.

- Duct Roughness: The internal surface roughness of the duct material affects friction. Rougher surfaces lead to higher pressure drop.

- Fittings and Obstructions: Bends, elbows, dampers, and other fittings introduce additional resistance to airflow, causing significant pressure drops beyond that from frictional losses in straight duct sections.

Equivalent Length: A Simplified Approach to Complexities

The concept of equivalent length simplifies the calculation of pressure drop by expressing the pressure drop contribution of fittings and other obstructions in terms of an equivalent length of straight duct. Instead of calculating the pressure drop for each fitting individually (which can be complex), we assign each fitting an equivalent length of straight duct that would cause the same pressure drop. This simplifies the overall pressure drop calculation by reducing everything to a single, easy-to-manage parameter – the total equivalent length of the duct system.

Calculating Equivalent Length for Fittings

The equivalent length of a fitting depends on several factors, including:

- Type of Fitting: Elbows, tees, dampers, and other fittings all have different pressure drop characteristics. Sharp bends cause significantly more pressure drop than gradual bends.

- Fitting Geometry: The precise dimensions of the fitting, such as the radius of an elbow or the angle of a tee, significantly impact pressure drop.

- Flow Rate: The pressure drop across a fitting is dependent on the air velocity.

Determining the equivalent length for each fitting usually involves referring to manufacturer's data, engineering handbooks (like the ASHRAE Handbook), or using specialized software. These resources provide tables or equations that relate the equivalent length to the fitting's type and dimensions. For example:

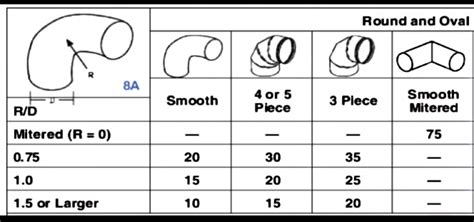

- Elbows: The equivalent length of an elbow is often expressed as a multiple of the elbow's diameter. A 90-degree elbow might have an equivalent length of 30 times its diameter. The exact multiplier depends on the elbow's radius and the flow conditions.

- Tees: The equivalent length of a tee depends on whether the flow is through the run or the branch. The branch typically experiences greater resistance.

- Dampers: Dampers introduce significant pressure drop, and their equivalent length is highly dependent on the damper's position. A fully open damper will have a relatively small equivalent length, while a nearly closed damper will have a considerably larger equivalent length.

Equivalent Length Calculation Methods

Several methods exist for calculating the total equivalent length of a duct system. The simplest approach involves summing the equivalent length of each fitting and the actual length of the straight duct sections.

1. The Summation Method:

This is a straightforward method, especially for simpler duct systems. It involves:

- Measuring the actual length of all straight duct sections.

- Determining the equivalent length of each fitting from manufacturer data or handbooks.

- Summing the actual lengths and equivalent lengths of all components. This total represents the system's equivalent length.

2. The Loss Coefficient Method:

This more sophisticated method involves using loss coefficients, denoted as "K," for each fitting. The loss coefficient represents the pressure drop across a fitting relative to the velocity pressure of the airflow. The total pressure drop is calculated by summing the pressure drop due to friction in the straight ducts and the pressure drops across each fitting, determined from the respective K-values and velocity pressure. The equivalent length can then be back-calculated from the total pressure drop. This approach offers better accuracy, especially for complex systems with many fittings.

3. Using Specialized Software:

HVAC design software packages typically include sophisticated algorithms for calculating pressure drop and equivalent length. These programs account for various factors, including duct geometry, fitting types, airflow rates, and air properties, resulting in more precise calculations than manual methods.

Non-Circular Ducts: Added Complexity

Calculating the equivalent length for non-circular ducts (like rectangular ducts) introduces added complexity. The friction factor (a measure of frictional resistance) is higher for non-circular ducts compared to circular ducts of equivalent cross-sectional area. To account for this, adjustment factors or equivalent diameters are often used to effectively convert the non-circular duct into an equivalent circular duct for simplified calculations. The equivalent diameter is calculated to give the same frictional losses as the actual non-circular duct.

Factors Affecting Accuracy

Several factors can influence the accuracy of equivalent length calculations:

- Flow Regime: The accuracy of calculations relies on the assumption of a specific flow regime (e.g., laminar or turbulent). Transitional flow regimes can lead to errors.

- Air Properties: The accuracy depends on using accurate values for air density, viscosity, and temperature.

- Duct Roughness: Accurate estimations of duct surface roughness are crucial.

- Fitting Data: The reliability of the equivalent length or loss coefficient data for fittings is essential.

Importance of Accurate Equivalent Length Determination

Accurate determination of equivalent length is vital for several reasons:

- Proper Fan Selection: The fan must be sized to overcome the total pressure drop across the duct system, including friction losses and fitting losses. Incorrect equivalent length calculations lead to improper fan selection, resulting in either insufficient airflow or oversized and inefficient fans.

- Optimized System Performance: Accurate pressure drop calculations ensure optimal airflow distribution throughout the system, preventing under- or over-ventilation of different zones.

- Energy Efficiency: A well-designed duct system, based on accurate equivalent length calculations, minimizes energy consumption by optimizing fan operation.

- Cost Savings: Avoiding oversizing or undersizing of the ductwork and fans translates to significant cost savings during both installation and operation.

Conclusion: A Critical Parameter in HVAC Design

Determining the equivalent length of a duct is a critical step in HVAC system design. While simple summation methods can be sufficient for simpler systems, more advanced methods and software are often required for complex duct layouts. Understanding the factors influencing pressure drop, the various methods for calculating equivalent length, and the potential sources of error are essential for HVAC professionals to design efficient, effective, and cost-optimized systems. Accurate calculation of equivalent length directly impacts the performance, energy efficiency, and overall cost-effectiveness of the entire HVAC system. Therefore, meticulous attention to detail and the use of appropriate calculation methods are crucial for successful HVAC design and implementation.

Latest Posts

Latest Posts

-

Cdl Combination Test Questions And Answers Pdf

Mar 18, 2025

-

Life Insurance Exam Questions And Answers Pdf

Mar 18, 2025

-

The Direct Carry Is Used To Transfer A Patient

Mar 18, 2025

-

The Emancipation Proclamation Of January 1 1863 Quizlet

Mar 18, 2025

-

These Cards Will Get You Drunk Quizlet

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about How Is The Equivalent Length Of A Duct Determined . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.