The Condenser Is Designed To _________ Heat.

Breaking News Today

Mar 20, 2025 · 6 min read

Table of Contents

The Condenser is Designed to Reject Heat

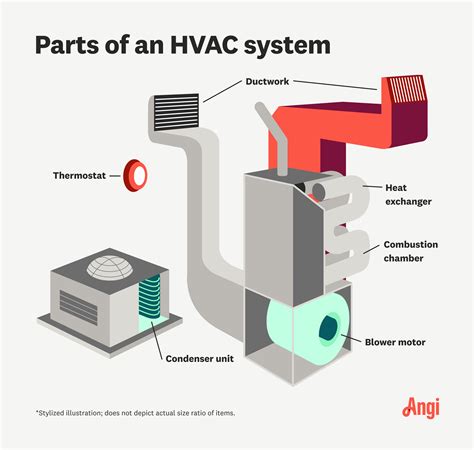

A condenser, a crucial component in various thermodynamic systems, isn't designed to create or store heat; its primary function is to reject heat. Understanding this fundamental principle is key to grasping its role in everything from air conditioning systems to power generation plants. This article delves deep into the intricacies of condensers, explaining their design principles, different types, applications, and the crucial role heat rejection plays in their operation.

Understanding the Concept of Heat Rejection

Before we delve into the specifics of condensers, let's clarify what "heat rejection" entails. Heat rejection is the process of transferring thermal energy from a system to its surroundings. This transfer aims to lower the temperature of the system, often a necessary step in many industrial and technological processes. The efficiency of a condenser is directly tied to its effectiveness in rejecting heat. A poorly designed or maintained condenser will fail to reject sufficient heat, leading to reduced efficiency and potential system failure.

How Condensers Reject Heat: The Mechanism

Condensers achieve heat rejection primarily through heat transfer. They utilize various mechanisms, but the core principle remains consistent: transferring heat from a hotter substance (the refrigerant or working fluid) to a cooler medium (typically air or water). This heat transfer usually occurs via one or a combination of the following:

1. Conduction:

Conduction involves the direct transfer of heat through a material. In a condenser, heat from the hot refrigerant flows through the condenser's walls, which are typically made of highly conductive materials like copper or aluminum. The design often incorporates fins to increase the surface area for improved heat transfer via conduction.

2. Convection:

Convection is the transfer of heat through the movement of fluids. Once the heat is conducted through the condenser walls, it's transferred to the surrounding fluid (air or water) through convection. The cooler fluid absorbs the heat, increasing its temperature, and carrying it away from the condenser. The design of the condenser's flow channels significantly influences the effectiveness of convective heat transfer. Turbulent flow, for instance, enhances heat exchange compared to laminar flow.

3. Radiation:

While less significant than conduction and convection in most condensers, radiative heat transfer can still play a role. Heat is emitted from the condenser's surface in the form of infrared radiation. This radiant heat is then absorbed by the surroundings, contributing to the overall heat rejection process.

Types of Condensers: A Diverse Range of Applications

Condensers come in various shapes and sizes, each designed to optimize heat rejection based on specific applications and operating conditions. Here are some common types:

1. Air-Cooled Condensers:

These condensers use air as the cooling medium. They are relatively simple and inexpensive but require a large surface area to dissipate heat effectively. This makes them suitable for smaller applications or situations where water is scarce. They're commonly found in small refrigeration systems, air conditioning units, and some industrial applications. The design often incorporates fans to increase airflow and improve heat rejection efficiency.

2. Water-Cooled Condensers:

Water-cooled condensers use water as the cooling medium, offering significantly higher heat transfer rates than air-cooled condensers. This makes them suitable for large-scale applications where high heat rejection capacity is crucial. They are commonly used in power plants, large industrial refrigeration systems, and HVAC systems in large buildings. The design often involves shell-and-tube configurations, where water flows through tubes inside a shell containing the hot refrigerant.

3. Evaporative Condensers:

Evaporative condensers combine the principles of water cooling and evaporation to enhance heat rejection. Water is sprayed over the condenser's surface, and as it evaporates, it absorbs a considerable amount of heat, leading to a more efficient heat rejection process. These condensers are particularly well-suited for applications where water is relatively scarce or where minimizing water consumption is critical. They often find use in hot, dry climates.

4. Shell and Tube Condensers:

These condensers are widely used in industrial applications due to their robust design and high heat transfer efficiency. The refrigerant flows through tubes housed within a larger shell, with the cooling fluid (usually water) flowing over the tubes. The large surface area provided by the numerous tubes allows for efficient heat exchange. This configuration is excellent for handling large amounts of heat and high pressures.

5. Plate Condensers:

Plate condensers consist of a series of corrugated plates, with the refrigerant and cooling fluid flowing through channels created by the plates. Their compact design makes them space-saving and efficient. The corrugated surface increases the surface area for better heat transfer. They are commonly used in smaller refrigeration systems and air conditioning units.

Factors Affecting Condenser Performance

Several factors influence the effectiveness of a condenser in rejecting heat:

-

Condenser Design: The geometry and materials used in the condenser significantly impact its heat transfer capabilities. The surface area, flow path design, and material conductivity all play crucial roles.

-

Cooling Fluid Temperature and Flow Rate: The temperature and flow rate of the cooling medium (air or water) directly affect the rate of heat transfer. Lower cooling fluid temperature and higher flow rates improve heat rejection.

-

Refrigerant Properties: The properties of the refrigerant, such as its boiling point and latent heat of vaporization, affect the amount of heat that needs to be rejected.

-

Fouling: Over time, deposits can accumulate on the condenser surfaces (fouling), reducing heat transfer efficiency. Regular cleaning and maintenance are essential for optimal performance.

The Importance of Efficient Heat Rejection

Efficient heat rejection is paramount for several reasons:

-

System Efficiency: A well-designed condenser ensures efficient operation of the entire system, whether it's a refrigeration cycle, power plant, or industrial process. Inefficient heat rejection leads to reduced system performance and increased energy consumption.

-

System Stability: Failure to reject sufficient heat can lead to overheating, potentially causing damage to the system's components and system instability.

-

Environmental Impact: Efficient condensers minimize energy waste, reducing the environmental footprint of the system.

Troubleshooting Condenser Issues

If a condenser isn't functioning optimally, several problems could be at play:

-

Fouling: Regular cleaning is crucial to remove dirt, scale, and other deposits that impede heat transfer.

-

Air Leaks: Air in the system can reduce efficiency. Leaks need to be identified and sealed.

-

Malfunctioning Fans: In air-cooled condensers, faulty fans can significantly reduce airflow, impairing heat rejection.

-

Low Cooling Fluid Flow: Insufficient cooling fluid flow can hinder efficient heat transfer. Check pumps and flow rates.

-

Clogged Tubes: In shell and tube condensers, clogged tubes can impede refrigerant flow and reduce heat transfer efficiency.

Conclusion: The Cornerstone of Efficient Thermal Systems

The condenser plays a pivotal role in a wide range of technological applications. Its primary function, rejecting heat, is not merely a detail but rather the cornerstone of its operation. Understanding the mechanisms of heat rejection, the diverse types of condensers, and the factors affecting their performance is vital for designing, operating, and maintaining efficient thermal systems. By optimizing condenser design and maintenance, we can enhance system efficiency, reduce energy consumption, and minimize environmental impact. The ability to efficiently reject heat is fundamental to the success of countless industrial and technological processes. This detailed exploration of condenser design and function should provide a comprehensive understanding of this crucial component in the world of thermodynamics and engineering.

Latest Posts

Latest Posts

-

Which Of The Following Statements About Enzymes Is Not True

Mar 21, 2025

-

A Burn That Is Characterized By Redness And Pain

Mar 21, 2025

-

Orthodontic Fixed Appliances Are Also Known As What

Mar 21, 2025

-

To Correct A Drive Wheel Braking Skid You Should

Mar 21, 2025

-

When Confronted With Capture Medical Personnel And Chaplains

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about The Condenser Is Designed To _________ Heat. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.