The Operating Principle Of Float-type Carburetors Is Based On The

Breaking News Today

Mar 29, 2025 · 7 min read

Table of Contents

The Operating Principle of Float-Type Carburetors is Based on the Precise Balancing of Fuel and Air

The internal combustion engine, a marvel of engineering, relies on a precise mixture of fuel and air for efficient combustion. In older vehicles and some smaller engines, this crucial task is handled by the carburetor, a mechanical device that meters and mixes fuel with air before it enters the engine's cylinders. While fuel injection systems have largely replaced carburetors in modern vehicles, understanding the float-type carburetor's operating principle remains valuable for enthusiasts, mechanics, and anyone interested in the history and mechanics of internal combustion engines. This in-depth exploration delves into the intricate workings of this ingenious device, highlighting its key components and explaining how they interact to deliver the perfect fuel-air blend.

The Fundamental Principle: Maintaining a Constant Fuel Level

At the heart of the float-type carburetor lies a simple yet elegant principle: maintaining a constant fuel level within the carburetor's float bowl. This constant level ensures a consistent fuel supply regardless of engine speed or demand. This seemingly straightforward task is achieved through a cleverly designed system involving several key components:

1. The Float Bowl: The Fuel Reservoir

The float bowl is a reservoir that holds the fuel supply. Its design ensures that fuel remains at a consistent level, preventing fuel starvation or flooding the engine. The shape and size of the float bowl are critical in determining the carburetor's capacity and its ability to handle variations in fuel demand. A poorly designed or damaged float bowl can significantly impact the carburetor's performance and lead to engine problems.

2. The Float: A Crucial Level Sensor

The float is a buoyant component that acts as a level sensor within the float bowl. It's typically made of a lightweight material, such as aluminum or plastic, and is attached to a pivoted lever or arm. As the fuel level in the bowl rises, the float rises accordingly. Conversely, as the fuel level drops, the float descends. This simple yet crucial mechanism is the foundation upon which the entire fuel metering system operates.

3. The Needle Valve: Controlling Fuel Flow

The needle valve is a precisely engineered component that regulates the flow of fuel into the float bowl. It's connected to the float's lever, so when the float rises (indicating a full bowl), the needle valve closes, shutting off the fuel supply. When the fuel level drops, the float descends, opening the needle valve and allowing more fuel to flow into the bowl. This system maintains a constant fuel level, ensuring a reliable fuel supply to the engine. The needle valve’s precise design is crucial for preventing both fuel starvation and overflowing. Wear and tear on the needle valve can lead to inconsistent fuel delivery and poor engine performance.

4. The Inlet Needle and Seat: A Precise Seal

The inlet needle and seat work in conjunction with the needle valve to provide a leak-proof seal. The inlet needle is a precisely machined component that sits within the seat, creating a tight seal when the needle valve is closed. Any imperfection in the needle and seat will result in fuel leakage, leading to fuel loss and potentially damaging the engine. The quality of the needle and seat is paramount to the carburetor's reliable operation.

From Fuel Level to Fuel-Air Mixture: Venturi Effect and Metering System

Maintaining a constant fuel level is only half the battle. The carburetor must also accurately meter the fuel and mix it with the correct amount of air for optimal combustion. This is achieved through the Venturi effect and a sophisticated system of jets and passages.

5. The Venturi: Creating Low Pressure

The Venturi is a constricted section within the carburetor's airflow path. As air flows through this constricted area, its velocity increases significantly, resulting in a decrease in pressure according to Bernoulli's principle. This lower pressure is crucial for drawing fuel from the float bowl into the airstream. The precise shape and size of the Venturi are crucial for determining the air velocity and pressure drop. Modifications to the Venturi can alter the engine's performance characteristics.

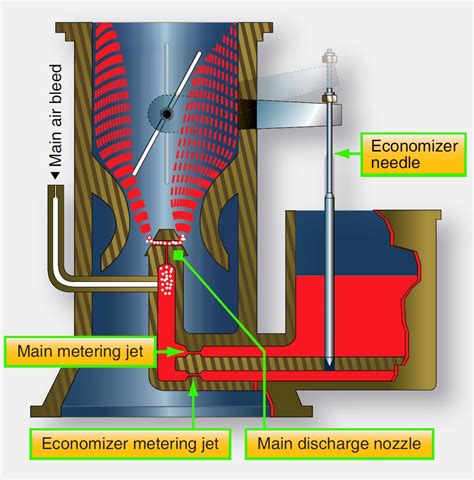

6. The Main Jet: Metering Fuel Flow

The main jet is a precisely calibrated orifice located within the Venturi. The low pressure created by the Venturi draws fuel from the float bowl through the main jet. The size of the main jet determines the amount of fuel drawn into the airstream, directly influencing the fuel-to-air ratio. The main jet is a critical component for tuning the carburetor to the specific needs of the engine. Different engines and operating conditions may require different size main jets for optimal performance.

7. The Idle Circuit: Ensuring Smooth Low-Speed Operation

At low engine speeds, the Venturi effect alone is insufficient to draw enough fuel. The idle circuit provides fuel at low speeds, preventing stalling. It consists of a separate passage and jet that feeds fuel directly into the airstream, bypassing the Venturi. The idle circuit's functionality is vital for smooth engine operation at low speeds. Proper adjustment of the idle circuit is crucial for ensuring a smooth idle and preventing stalling.

8. The Accelerator Pump: Providing Enrichment During Acceleration

During acceleration, the engine demands a richer fuel-air mixture to prevent lean-out and hesitation. The accelerator pump delivers a shot of extra fuel into the airstream when the throttle is opened quickly. This pump is usually a small diaphragm-type pump actuated by the throttle linkage. The amount of fuel delivered by the accelerator pump is crucial for smooth acceleration and preventing bogging down.

Beyond the Basics: Understanding the Variations

While the fundamental operating principle remains consistent across float-type carburetors, variations exist in design and complexity depending on the application and engine requirements. These variations often involve additional components or modifications to existing ones, including:

9. Choke System: Enrichment for Cold Starts

Cold start enrichment is crucial for easier starting in cold weather. The choke restricts airflow, creating a richer mixture for easier ignition. This is achieved by either partially blocking the airflow path or enriching the fuel mixture. This often involves a choke plate or a system that enriches the idle circuit.

10. Power Valve: Providing Additional Fuel at Higher Loads

Some carburetors incorporate a power valve, which opens at higher engine loads to provide additional fuel, thus preventing lean-out during high-demand situations. This ensures optimal performance across a broader range of engine speeds and loads.

11. Air Bleeds: Fine-tuning the Mixture

Air bleeds are small passages that introduce air into the fuel stream, helping to atomize the fuel and further refine the fuel-air mixture. The precise location and size of air bleeds influence the mixture's characteristics. Proper adjustment of air bleeds is critical for achieving optimal engine performance.

Troubleshooting and Maintenance

Understanding the float-type carburetor's operating principle is essential for troubleshooting common issues. Problems such as flooding, stalling, poor acceleration, or rough idling often stem from malfunctions in the various components. Regular maintenance, including cleaning, adjustment, and occasional part replacement, is crucial for maintaining the carburetor's performance and ensuring the engine's proper operation. Improper maintenance can lead to poor fuel economy, reduced engine power, and even engine damage.

The Legacy of the Float-Type Carburetor

While fuel injection systems have largely superseded float-type carburetors in modern vehicles, their ingenuity and elegant simplicity remain noteworthy. Understanding their operation provides valuable insight into the history and mechanics of internal combustion engines, showcasing the ingenuity of early automotive engineering. Moreover, they remain relevant for maintaining older vehicles and in certain niche applications where cost-effectiveness and simplicity are paramount. The principles behind their operation continue to inform the design and development of modern fuel delivery systems, emphasizing the enduring legacy of this remarkable device.

This detailed explanation, incorporating SEO best practices such as keyword optimization (float-type carburetor, carburetor operation, fuel-air mixture, Venturi effect, etc.), semantic integration, and structured content using headings and subheadings, aims to provide a comprehensive understanding of the float-type carburetor's operating principles and its significant role in the history and development of internal combustion engines.

Latest Posts

Latest Posts

-

A Symptom Of Oral Cancer Includes Quizlet

Mar 31, 2025

-

Dosage Calculation 3 0 Safe Dosage Test Quizlet

Mar 31, 2025

-

Biol 2401 Anatomy And Physiology I Quizlet

Mar 31, 2025

-

Hesi Lpn To Adn Entrance Exam Quizlet

Mar 31, 2025

-

Anatomy Of The Respiratory System Labster Quizlet

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about The Operating Principle Of Float-type Carburetors Is Based On The . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.