The Three Primary Goals Of Duct Design Are

Breaking News Today

Mar 20, 2025 · 7 min read

Table of Contents

The Three Primary Goals of Duct Design: Efficiency, Durability, and Cost-Effectiveness

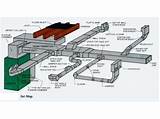

Designing a ductwork system is far more complex than it initially appears. It's not simply about connecting metal sheets; it's a crucial element of any HVAC system, directly impacting its performance, energy efficiency, and longevity. The three primary goals of duct design are efficiency, durability, and cost-effectiveness. These goals are intertwined, and successful design necessitates a careful balancing act between them. Let's delve deeper into each:

1. Efficiency: Optimizing Airflow and Minimizing Pressure Drop

Efficiency in duct design centers around optimizing airflow and minimizing pressure drop. This translates directly into the system's ability to deliver conditioned air effectively to the spaces it's designed to serve. Several factors contribute to achieving efficient ductwork:

A. Proper Sizing and Layout:

Accurate calculations are paramount. Ductwork must be sized appropriately to handle the required airflow volume without excessive velocity. Too small a duct will restrict airflow, leading to high pressure drop and reduced system performance. Conversely, an oversized duct will lead to wasted energy due to increased air velocity and pressure.

The layout of the duct system is equally crucial. Minimizing the total length of ductwork and the number of bends and fittings reduces pressure drop. Strategic placement of supply and return registers also contributes to balanced airflow throughout the building.

Careful consideration of the building's design and the location of the HVAC equipment is essential. This includes accounting for potential obstacles, such as walls, ceilings, and structural elements.

B. Minimizing Friction and Turbulence:

Friction and turbulence within the ductwork represent energy losses. Smooth interior surfaces minimize friction, allowing air to flow more easily. Properly designed transitions between different duct sizes help to minimize turbulence. Sharp bends and obstructions cause significant pressure drop, hence their avoidance is vital.

Using appropriate materials is vital. Galvanized steel remains a popular choice for its durability and relatively smooth surface. However, other materials like flexible ductwork (often used for smaller branches or in tight spaces) can contribute to increased friction. This factor must be considered during the selection process.

C. Balanced Airflow:

Achieving balanced airflow is a key aspect of efficiency. This means ensuring that the appropriate amount of air is delivered to each room or zone according to its specific heating and cooling needs. Improperly balanced airflow leads to some areas being too cold or too hot, compromising comfort and increasing energy consumption.

Careful design and, in many cases, post-installation balancing of dampers are necessary to fine-tune airflow distribution. This often involves utilizing specialized tools and techniques to ensure precise adjustment.

D. Air Leakage Prevention:

Air leakage in the ductwork system represents a significant energy loss. It can lead to reduced heating and cooling efficiency, as well as to issues with indoor air quality. Proper sealing and insulation of duct joints and connections are essential to minimize air leakage. This is especially important in areas with significant temperature differences, such as attics and crawl spaces.

Regular inspection and maintenance of the ductwork can help to identify and address any leaks that may develop over time. Sealant and mastic are crucial tools in the process of leak prevention.

2. Durability: Ensuring Long-Term Performance and Resistance to Damage

Durability in duct design ensures that the system remains functional and efficient for many years. This goal involves considering the system’s resistance to corrosion, damage, and degradation from various factors:

A. Material Selection:

The choice of materials directly influences durability. Galvanized steel is widely used for its resistance to corrosion and strength. However, other materials like aluminum or stainless steel offer superior corrosion resistance for specific applications or environments. The selection should consider the humidity and corrosive elements present in the environment where the system will be installed.

Flexible ductwork, while useful for certain applications, is generally less durable than rigid ductwork. Its use should be carefully considered based on its intended purpose and the expected wear and tear.

B. Proper Installation:

Proper installation is crucial for long-term durability. Securely fastening the ductwork components to prevent movement or vibration is vital. Loose connections or improperly supported sections can lead to damage over time. Adherence to industry best practices and standards during installation helps safeguard against premature system failure.

The use of appropriate tools and techniques is essential to ensure a professional, high-quality installation. Poor workmanship can significantly shorten the life span of a ductwork system.

C. Protection from Environmental Factors:

Exposure to moisture, extreme temperatures, and pests can degrade ductwork over time. Proper insulation helps to protect the system from temperature fluctuations and condensation. Installing the ductwork in protected locations, away from potential sources of damage, is crucial.

In environments with high humidity, selecting corrosion-resistant materials is crucial. Similarly, in areas with a significant pest population, measures must be taken to protect the ductwork from potential damage.

D. Access for Maintenance:

Designing the system with easy access for maintenance adds to its overall durability. Including access panels allows for easier inspection, cleaning, and repair of the ductwork. This preventative maintenance helps to extend the lifespan of the system by addressing potential issues early on.

Well-planned access points allow technicians to conduct thorough inspections and carry out repairs efficiently, reducing downtime and preventing major issues from developing.

3. Cost-Effectiveness: Balancing Performance with Budgetary Constraints

Cost-effectiveness in duct design involves optimizing the system's performance while keeping the initial investment and ongoing operational costs to a minimum. This balance is crucial and often involves trade-offs between efficiency, durability, and cost.

A. Material Costs:

The cost of materials varies depending on the type of ductwork used. While galvanized steel is relatively inexpensive, stainless steel or other specialized materials are more costly. Choosing the most appropriate material based on the specific needs of the project can significantly impact the overall cost.

This consideration extends to insulation, sealants, and other components. Choosing cost-effective materials without compromising quality is a necessary balancing act.

B. Installation Costs:

The cost of installation is dependent on various factors, including the complexity of the design, the labor rates, and the accessibility of the installation site. A well-planned and simple design can reduce installation costs compared to a more complex system. Optimizing the layout and minimizing the overall length of the ductwork can also contribute to lower installation costs.

Proper planning is vital to reduce potential unforeseen issues during the installation process. A well-defined plan can streamline installation and avoid costly delays.

C. Energy Costs:

The long-term energy costs associated with the system are a crucial factor in its overall cost-effectiveness. A well-designed, efficient system will minimize pressure drop and air leakage, reducing energy consumption for heating and cooling. The initial investment in a more energy-efficient system may be higher, but the long-term savings in energy costs will usually offset this higher upfront cost. This is a key element of lifecycle costing, comparing long-term costs against upfront expenses.

Energy efficiency improvements are a significant aspect of reducing operational costs over the lifespan of the HVAC system. This reflects the ongoing commitment to reducing overall expense.

D. Maintenance Costs:

The costs associated with maintenance over the lifetime of the system are also an important factor. A durable, well-designed system will require less frequent maintenance, reducing these costs. Regular maintenance, as discussed earlier, is also crucial to prevent major repairs that can be far more expensive. By designing for ease of access and maintenance, costs can be kept to a minimum over the long run.

Choosing high-quality materials and ensuring proper installation can substantially contribute to lowering overall maintenance costs over time. This is a testament to the value of careful planning and superior craftsmanship.

In conclusion, the three primary goals of duct design—efficiency, durability, and cost-effectiveness—are deeply interconnected. Achieving a balance between these goals requires careful consideration of numerous factors, including airflow dynamics, material selection, installation practices, and long-term operational costs. A successful duct design maximizes the efficiency of the HVAC system, ensures its long-term performance and reliability, and offers a cost-effective solution that benefits the building owner and occupants. It's a complex interplay of technical knowledge, careful planning, and thoughtful consideration of long-term implications.

Latest Posts

Latest Posts

-

What Is The Definition Of Freezing Your Credit Everfi

Mar 21, 2025

-

Jose 1 Of 1 En La Biblioteca

Mar 21, 2025

-

Describe A Situation In Which You May Experience Bypass

Mar 21, 2025

-

Spanish 1b Unit 6 Review Of Unit 1

Mar 21, 2025

-

Which Statement Best Describes A Lifestyle With Healthy Eating Habits

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about The Three Primary Goals Of Duct Design Are . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.