The Ultimate Goal Of Lean Operations Is To Have

Breaking News Today

Mar 29, 2025 · 6 min read

Table of Contents

The Ultimate Goal of Lean Operations Is to Have… Satisfied Customers Through Waste Elimination

The ultimate goal of lean operations isn't just about efficiency or cost reduction, though those are significant benefits. It's about creating a system that consistently delivers exceptional value to the customer by relentlessly eliminating waste. This means understanding what truly matters to your customer and optimizing every process to meet those needs effectively and efficiently. This article will delve deep into this ultimate goal, exploring the various facets of lean principles and how they contribute to ultimate customer satisfaction.

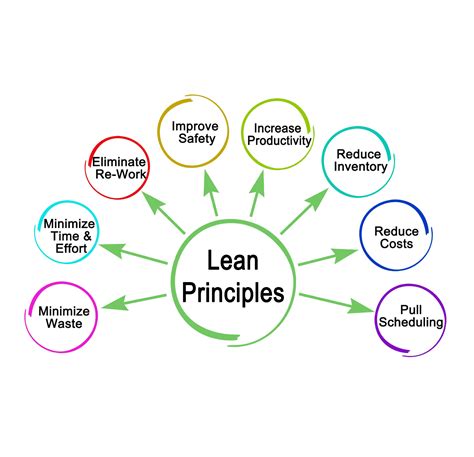

Understanding the Core Principles of Lean Operations

Before we dissect the ultimate goal, it's crucial to grasp the core principles that underpin lean operations. These principles, often attributed to the Toyota Production System (TPS), form the foundation for achieving operational excellence and customer delight.

1. Value Definition: Understanding Customer Needs

The journey to lean begins with a clear understanding of value from the customer's perspective. What are they willing to pay for? What problems are they trying to solve? This necessitates thorough market research, customer feedback analysis, and a deep understanding of their expectations. Without this crucial first step, all other lean efforts risk being misdirected. It's about identifying the "must-haves" and the "nice-to-haves" to prioritize features and processes.

2. Value Stream Mapping: Identifying Waste

Once value is defined, the next step is to map the entire value stream—all the steps and processes involved in delivering that value to the customer. This process reveals areas where waste (muda) exists. Value stream mapping is a powerful visual tool that allows organizations to identify bottlenecks, inefficiencies, and unnecessary activities that add cost and delay without adding value for the customer.

3. Waste Elimination: The 7 Muda (and More!)

Lean methodology identifies various types of waste, often categorized as the seven mudas:

- Transportation: Unnecessary movement of materials or information.

- Inventory: Excess stock that ties up capital and risks obsolescence.

- Motion: Unnecessary movement of people or equipment.

- Waiting: Idle time waiting for materials, information, or processes to complete.

- Overproduction: Producing more than is needed or demanded.

- Over-processing: Performing more work than is necessary to meet customer requirements.

- Defects: Errors and rework that lead to scrap, rework, and customer dissatisfaction.

However, the concept of waste extends beyond these seven. Lean thinkers often include:

- Underutilized Talent: Failing to leverage the skills and knowledge of employees.

- Non-standardized Processes: Inconsistent processes that lead to variations and errors.

- Extra Processing: Doing work that doesn't add value to the customer.

By systematically identifying and eliminating these forms of waste, organizations streamline their operations, reduce costs, and improve efficiency.

4. Continuous Improvement (Kaizen): A Never-Ending Journey

Lean isn't a one-time project; it's a continuous improvement journey. The Kaizen philosophy emphasizes ongoing incremental improvements through small, iterative changes. This involves empowering employees at all levels to identify and implement improvements, fostering a culture of innovation and problem-solving. Kaizen events, or focused improvement projects, are a common tool used to drive continuous improvement.

5. Respect for People: Empowering Employees

Lean operations highly value employee involvement and empowerment. Employees are considered the most valuable asset and are empowered to identify and solve problems, contribute ideas, and participate in decision-making. This fosters a culture of teamwork, collaboration, and continuous improvement, leading to increased employee satisfaction and engagement.

The Ultimate Goal: Satisfied Customers Through Waste Elimination

The ultimate goal of lean operations is to create a system that consistently delivers exceptional value to the customer by relentlessly eliminating waste. This isn't simply about reducing costs; it's about optimizing the entire value stream to meet customer needs in the most efficient and effective way possible.

This means:

- Faster Delivery Times: Lean processes aim to reduce lead times, getting products or services to the customer quicker.

- Higher Quality Products/Services: Waste elimination minimizes defects and errors, leading to higher quality outputs.

- Lower Costs: Efficient processes reduce waste, leading to cost savings that can be passed on to the customer.

- Increased Flexibility: Lean systems are often more adaptable to changing customer demands.

- Improved Customer Satisfaction: The ultimate measure of success is happy customers who are satisfied with the value received.

Satisfied customers translate to repeat business, positive word-of-mouth referrals, and ultimately, sustained business growth and profitability.

Implementing Lean Operations: A Step-by-Step Approach

Implementing lean operations is a structured process that requires careful planning and execution. Here’s a step-by-step approach:

- Define Value: Begin by clearly defining value from the customer’s perspective. Use various techniques like customer surveys, interviews, and focus groups to gain insights into their needs and expectations.

- Map the Value Stream: Create a visual representation of all the steps involved in delivering value to the customer. This includes both value-adding and non-value-adding activities.

- Identify Waste: Analyze the value stream map to identify areas where waste is present. Use the seven mudas (and beyond) as a framework.

- Develop Improvement Plans: Based on the identified waste, develop specific improvement plans to eliminate or reduce the waste. This may involve process re-engineering, technology upgrades, or employee training.

- Implement Improvements: Implement the improvement plans in a phased approach. Start with small, manageable changes and gradually implement larger changes as you gain experience.

- Monitor and Evaluate: Continuously monitor and evaluate the effectiveness of the implemented changes. Use key performance indicators (KPIs) to track progress and identify areas for further improvement.

- Standardize and Document: Once improvements are implemented, standardize the processes and document them to ensure consistency.

- Sustain Improvement: Embed lean principles into the organizational culture to ensure continuous improvement. Regular Kaizen events and employee involvement are crucial.

Lean Operations and Digital Transformation

The digital transformation of businesses presents exciting opportunities to leverage lean principles in novel ways. Data analytics, automation, and advanced technologies can drastically enhance waste elimination and efficiency. Here are a few examples:

- Predictive Analytics for Inventory Management: Analyzing historical data can predict demand fluctuations, minimizing excess inventory.

- Process Automation: Automating repetitive tasks reduces errors, improves efficiency, and frees up employees for higher-value work.

- Digital Collaboration Tools: Streamlining communication and collaboration across departments minimizes waiting and improves response times.

- Real-time Data Monitoring: Tracking key performance indicators (KPIs) in real time allows for proactive problem-solving and rapid adjustments.

Overcoming Challenges in Lean Implementation

Implementing lean operations is not without its challenges. Some common hurdles include:

- Resistance to Change: Employees may resist changes to established processes and procedures. Effective communication and training are crucial to overcome this resistance.

- Lack of Management Support: Lean initiatives require strong leadership support and commitment from top management.

- Insufficient Training: Employees need proper training and support to effectively implement lean principles.

- Inadequate Measurement: Without appropriate metrics to track progress, it’s difficult to assess the effectiveness of lean initiatives.

- Lack of a Continuous Improvement Culture: Lean is a journey, not a destination. A strong culture of continuous improvement is essential for long-term success.

Conclusion: The Ongoing Pursuit of Customer Satisfaction

The ultimate goal of lean operations is not a destination but a continuous pursuit of excellence. It's about fostering a culture of continuous improvement that relentlessly strives to eliminate waste and deliver exceptional value to the customer. By understanding customer needs, mapping value streams, eliminating waste, and empowering employees, organizations can achieve operational excellence and achieve that ultimate goal: satisfied customers. This satisfaction translates into loyalty, growth, and long-term success, making lean operations a strategic imperative for any business aiming for sustained prosperity in a competitive marketplace. The journey is challenging, but the rewards of consistently exceeding customer expectations are immeasurable.

Latest Posts

Latest Posts

-

Regional Impacts Of The Embargo Of 1807 The West

Mar 31, 2025

-

10 Interesting Facts About The Holocaust Quizlet

Mar 31, 2025

-

Ati Nursing Informatics And Technology Informatics Quizlet

Mar 31, 2025

-

Apoptosis Refers To Cell Death And Quizlet

Mar 31, 2025

-

Debt Consolidation Loans Can Be Used To Quizlet

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about The Ultimate Goal Of Lean Operations Is To Have . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.