Torque Is Measured At The Engine ____.

Breaking News Today

Mar 24, 2025 · 6 min read

Table of Contents

Torque is Measured at the Engine Crankshaft

Torque, the rotational force that an engine produces, is a critical performance metric often misunderstood. Understanding where and how it's measured is key to appreciating its importance in vehicle performance and engineering. This comprehensive guide will delve into the intricacies of torque measurement, exploring its relationship with horsepower, the role of the crankshaft, and the implications for different engine types and applications.

Understanding Torque and Its Significance

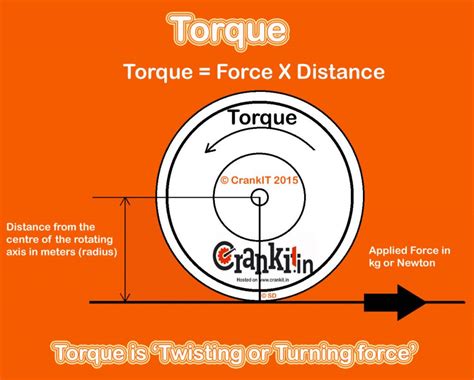

Torque, measured in Newton-meters (Nm) or pound-feet (lb-ft), represents the twisting force an engine exerts on its crankshaft. It's the force that accelerates the vehicle, overcomes resistance (like hills or inertia), and ultimately provides the feeling of power. Unlike horsepower, which represents the rate of doing work, torque represents the amount of rotational force. A higher torque figure at a specific engine speed signifies a greater ability to pull heavy loads or accelerate quickly.

Think of it this way: horsepower is how quickly you can get the job done, while torque is how much work you can do. A high-torque engine excels at pulling heavy trailers, climbing steep inclines, and providing strong acceleration at low speeds. A high-horsepower engine, on the other hand, emphasizes high speeds and rapid acceleration at higher RPMs.

The Crankshaft: The Heart of Torque Measurement

The engine crankshaft is the central component where torque is measured. This robust, rotating shaft is directly connected to the engine's pistons and converts the reciprocating linear motion of the pistons into rotational motion. The crankshaft's rotational force is precisely what we measure as engine torque. Various sensors and dynamometers strategically placed at or near the crankshaft are used for this precise measurement.

How Torque is Measured: A Deeper Dive

Measuring engine torque involves sophisticated techniques and equipment. The most common method utilizes a dynamometer, a specialized device that precisely measures the rotational force exerted by the engine crankshaft. There are different types of dynamometers, each with unique functionalities:

1. Eddy Current Dynamometers:

These dynamometers use electromagnetic induction to create a resisting force against the rotating crankshaft. By measuring the electrical current required to produce this resisting force, the dynamometer precisely determines the torque output of the engine. Eddy current dynamometers are known for their accuracy and smooth operation, making them ideal for precise torque measurement across a wide range of engine speeds.

2. Absorption Dynamometers:

Absorption dynamometers absorb the engine's power by dissipating it as heat. This dissipation is carefully measured to determine the torque produced. While less common in modern engine testing, they are still employed in specific applications.

3. Inertia Dynamometers:

Inertia dynamometers measure torque by accelerating a known inertial load. By measuring the rate of acceleration, the torque can be calculated. These are often simpler and more cost-effective than other types but may offer lower precision for very high torque measurements.

The Relationship Between Torque and Horsepower

While distinct, torque and horsepower are intrinsically linked through a mathematical relationship involving engine speed (RPM). The formula is:

Horsepower (hp) = (Torque (lb-ft) x RPM) / 5252

This equation highlights that horsepower is dependent on both torque and engine speed. An engine can produce high torque at low RPMs, leading to strong low-end acceleration, but the overall horsepower might be relatively lower. Conversely, an engine might generate high horsepower at high RPMs, resulting in impressive top-end speed but potentially less low-end grunt.

This relationship explains why comparing engines solely based on horsepower isn't always sufficient. A higher torque figure at lower RPMs often translates to better real-world drivability and towing capacity. This is particularly important for vehicles designed for heavy hauling or off-road driving.

Factors Affecting Engine Torque

Several factors influence the torque produced by an engine:

-

Engine Displacement: Larger engine displacements generally produce higher torque. This is because larger cylinders can accommodate more air and fuel, leading to a more powerful combustion process.

-

Compression Ratio: A higher compression ratio increases the pressure and temperature within the combustion chamber, resulting in a more forceful explosion and increased torque.

-

Engine Design: The design of the engine, including the type of combustion cycle (e.g., four-stroke, two-stroke), valvetrain, and intake system, all significantly impact torque output. Different designs optimize for various torque curves, some favoring low-end torque while others focus on high-RPM power.

-

Turbocharging and Supercharging: Forced induction systems like turbochargers and superchargers increase the amount of air entering the engine, leading to increased combustion and higher torque output, especially at higher engine speeds.

-

Fuel Type: The type of fuel used, such as gasoline or diesel, can significantly impact torque. Diesel fuel typically results in higher torque at lower RPMs compared to gasoline.

Torque Curves and Their Interpretation

Engine torque is not constant across the entire RPM range. Instead, it varies, and this variation is typically depicted on a graph called a torque curve. The torque curve shows the torque output at different engine speeds. Analyzing the torque curve is crucial for understanding an engine's characteristics and performance capabilities.

A "flat" torque curve indicates consistent torque delivery across a wide RPM range, ideal for smooth and predictable power delivery. A "peaky" torque curve might show high torque at a narrow RPM band, suggesting strong performance within that specific range but potentially less power outside of it.

Understanding the shape of the torque curve helps engineers optimize engine performance for specific applications. For example, a truck engine might be designed for a high and flat torque curve at lower RPMs for better towing capabilities, whereas a sports car engine might prioritize a peakier torque curve at higher RPMs for maximum speed.

Torque Measurement in Different Engine Types

The method of torque measurement remains consistent across various engine types, but the specific implementation might vary slightly depending on the engine's configuration.

Internal Combustion Engines (ICE): Whether it's a gasoline or diesel engine, the crankshaft remains the central point for torque measurement. Dynamometers are used to measure the rotational force exerted by the crankshaft.

Electric Motors: Electric motors also generate torque, although the measurement technique is slightly different. Instead of measuring the crankshaft's rotation, the torque is measured at the motor's output shaft using similar dynamometer principles.

Applications and Implications of Torque Measurement

Precise torque measurement has far-reaching implications across various applications:

-

Vehicle Performance Engineering: Engine designers rely on torque measurements to optimize engine performance, ensuring optimal torque delivery for various driving conditions. This information influences the design of components such as the transmission, drivetrain, and suspension systems.

-

Quality Control: Torque measurements are critical during engine manufacturing to ensure each engine meets the specified performance criteria. This contributes to the reliability and consistency of vehicle performance.

-

Research and Development: Torque data is invaluable for research and development efforts, allowing engineers to study the effects of different design parameters and optimize engine efficiency and performance.

-

Troubleshooting and Diagnostics: Torque measurements can help diagnose engine problems. Lower-than-expected torque can indicate various issues, such as insufficient air intake, fuel delivery problems, or mechanical defects.

Conclusion: The Crankshaft's Crucial Role

The crankshaft sits at the heart of torque measurement, serving as the pivotal point where the engine's rotational force is measured. Understanding torque's significance, the methods for its measurement, and its relationship with horsepower are essential for anyone interested in automotive engineering, performance tuning, or simply appreciating the mechanics of internal combustion engines. The torque curve, a vital graphical representation of an engine's torque output across different speeds, offers insights into an engine's character and suitability for specific applications. From optimizing vehicle performance to ensuring quality control, accurate torque measurement plays a crucial role in numerous aspects of engine design, manufacturing, and maintenance.

Latest Posts

Latest Posts

-

Divided Loyalty Between President And Agency They Command

Mar 28, 2025

-

An Ideal Habitat With Unlimited Resources Is Associated With

Mar 28, 2025

-

In Shakespeares Hamlet What Plot Events Undermine Queen Gertrudes Confidence

Mar 28, 2025

-

What Statement Describes A Characteristic Of Mac Addresses

Mar 28, 2025

-

Most Spanish Speaking People Have Three Last Names

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about Torque Is Measured At The Engine ____. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.