What Is The Recommended Opening For Valves

Breaking News Today

Mar 20, 2025 · 5 min read

Table of Contents

What is the Recommended Opening for Valves?

Valves are ubiquitous in countless industrial and domestic applications, controlling the flow of liquids, gases, and slurries. Understanding the recommended opening for a valve is crucial for efficient operation, safety, and the longevity of the valve itself. There's no single "correct" answer, as the ideal opening depends heavily on several factors. This comprehensive guide will delve into these factors, providing practical advice and best practices for various valve types.

Factors Influencing Recommended Valve Opening

Several interconnected factors determine the optimal opening for any given valve. Ignoring these can lead to premature wear, inefficient operation, and even catastrophic failure.

1. Valve Type: A Crucial First Consideration

Different valve types have distinct operating characteristics and recommended opening procedures. For example:

-

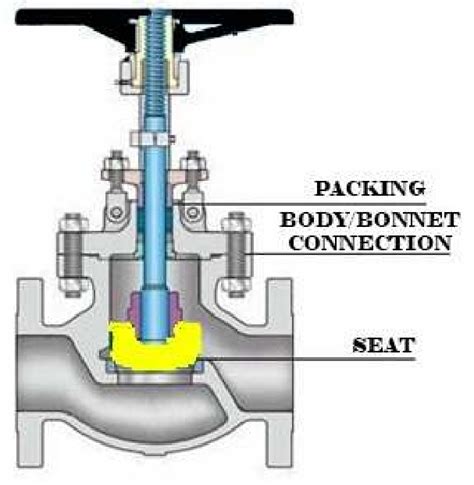

Globe Valves: Known for their excellent throttling capabilities, globe valves are often opened gradually to avoid erosion and cavitation. A sudden, full opening can cause a rapid change in flow velocity, leading to damage. The recommended opening is often a slow, incremental approach.

-

Gate Valves: Primarily designed for fully open or fully closed operation, gate valves are generally not recommended for throttling. Operating them partially open can cause significant wear on the gate and seat, potentially leading to leakage. The ideal opening is either fully open or fully closed.

-

Ball Valves: Offering a simple on/off function, ball valves are quick to operate. However, even with ball valves, it's advisable to avoid slamming them open or shut, especially in high-pressure applications. A controlled opening and closing prevents undue stress on the valve components.

-

Butterfly Valves: Similar to ball valves in their simplicity, butterfly valves are generally opened and closed quickly. However, for precise flow control, a more gradual approach may be necessary. Again, avoiding sudden movements is key to longevity.

-

Check Valves: These valves automatically open and close based on flow direction. Their opening isn't manually controlled; hence, there's no specific recommended opening procedure. Focus instead on ensuring correct installation and maintenance to prevent malfunctions.

2. Fluid Properties: Viscosity and Corrosiveness

The nature of the fluid being controlled significantly impacts valve operation.

-

Viscosity: Highly viscous fluids require slower, more controlled opening to avoid excessive pressure build-up and potential valve damage. The force needed to move a viscous fluid necessitates a gentler approach.

-

Corrosiveness: Corrosive fluids can accelerate valve wear. Slow, measured openings minimize the contact time between the corrosive fluid and the valve components, mitigating potential damage.

-

Abrasiveness: Abrasive fluids can cause significant wear and tear on valve components. Gentle opening and closing helps reduce erosion and prolong valve lifespan.

3. Pressure and Temperature: High-Stress Environments

Operating conditions significantly influence the recommended opening.

-

High Pressure: High-pressure applications necessitate a controlled, gradual opening to avoid water hammer or pressure surges that can damage the valve and associated piping.

-

High Temperature: High-temperature environments can lead to thermal expansion and stress on the valve components. A slow, steady opening minimizes thermal shock and potential damage.

4. Piping System: Considering the Entire Network

The valve isn't an isolated entity; it's part of a larger piping system.

-

Piping Material: The piping material influences the pressure surges and vibrations that can occur during valve operation. Consider this aspect when determining the opening speed.

-

Piping Size: Larger pipe diameters require a slower opening to prevent excessive pressure fluctuations.

5. Valve Size and Capacity: Matching the Flow Requirements

The valve's size and capacity directly influence the opening speed.

-

Small Valves: These often require less cautious handling than larger valves; however, this is not always true.

-

Large Valves: Large valves require more controlled opening due to the increased volume of fluid involved. Rapid opening can lead to excessive stress and potential damage.

Recommended Opening Procedures: Practical Guidelines

While there's no universal procedure, these guidelines provide a solid foundation:

-

Start Slow: Always begin with a slow, gradual opening, especially for globe valves and those handling high-pressure or viscous fluids.

-

Observe and Adjust: Monitor the pressure gauges and flow meters during opening to ensure smooth operation and identify any abnormalities.

-

Avoid Slamming: Never forcefully slam a valve open or closed. This causes significant stress on internal components, leading to premature wear and potential failure.

-

Incremental Approach: For throttling applications, use an incremental approach, gradually adjusting the valve position to achieve the desired flow rate. This is especially important with globe valves.

-

Regular Maintenance: Regular maintenance and inspection of valves are critical for detecting wear and tear and preventing unexpected failures.

Consequences of Incorrect Valve Opening

Incorrect valve operation can lead to several detrimental consequences:

-

Premature Valve Failure: Sudden changes in pressure or flow can damage valve components, leading to shortened lifespan and costly replacements.

-

Pipe Damage: Excessive pressure surges can damage pipes, fittings, and other components within the system.

-

Leaks: Improper operation can cause leaks, leading to waste, environmental damage, and safety hazards.

-

Process Disruptions: Valve malfunction can disrupt processes, leading to production delays and losses.

-

Safety Hazards: Valve failure can result in significant safety hazards, particularly in high-pressure or hazardous material applications.

Conclusion: A Balanced Approach

The optimal opening for a valve is not a singular value but a function of multiple factors. A thorough understanding of the valve type, fluid properties, operating conditions, and piping system is crucial for determining the appropriate opening procedure. Prioritizing a slow, controlled opening, combined with regular maintenance and observation, will significantly extend valve life, improve operational efficiency, and enhance safety. Remember, preventing problems is far cheaper than fixing them. A proactive approach to valve operation will pay dividends in the long run.

Latest Posts

Latest Posts

-

Bladder Retraining Following Removal Of An Indwelling Catheter Begins With

Mar 21, 2025

-

Identify The Defining Characteristics Of An Organization

Mar 21, 2025

-

This Seals Up Gaps In A Piece Of Dna

Mar 21, 2025

-

Driving Cars Lowers The Ph Of The Oceans By

Mar 21, 2025

-

Scaffold Are The Workers Qualified To Design

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about What Is The Recommended Opening For Valves . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.