What Is Unique About An Azeotropic Refrigerant Mixture

Breaking News Today

Mar 21, 2025 · 6 min read

Table of Contents

What's Unique About an Azeotropic Refrigerant Mixture?

Refrigeration is a cornerstone of modern life, underpinning everything from food preservation to air conditioning. The heart of any refrigeration system is the refrigerant, and in recent years, azeotropic refrigerant mixtures have emerged as a compelling alternative to traditional single-component refrigerants. Understanding their unique properties is crucial for engineers, technicians, and anyone interested in sustainable and efficient cooling technologies. This article delves deep into the characteristics that make azeotropic refrigerant mixtures so distinctive and valuable.

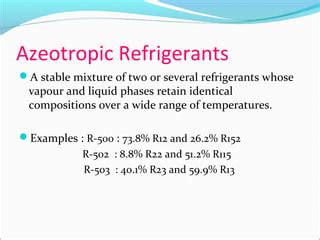

Understanding Azeotropes: A Blend with a Single Boiling Point

Before exploring the unique aspects of azeotropic refrigerant mixtures, it's fundamental to understand what an azeotrope actually is. An azeotrope is a special type of mixture of two or more liquids that boils at a constant temperature and composition. This means that unlike a typical mixture, where the components will boil off at different temperatures, an azeotrope behaves as a single entity during boiling. This constant boiling point is the key to its unique refrigerating properties. This contrasts with zeotropic mixtures, where the boiling point varies throughout the evaporation process.

The Significance of Constant Boiling Point in Refrigeration

The constant boiling point of an azeotropic refrigerant mixture is critical for several reasons:

-

Predictable Performance: The consistent boiling point ensures predictable and stable performance throughout the refrigeration cycle. This simplifies system design and optimization, reducing the complexity of calculations and control systems. The lack of temperature drift during evaporation means more consistent cooling capacity.

-

Simplified System Design: Since the mixture behaves like a single substance, system design is simpler compared to systems using zeotropic blends. This translates to cost savings in manufacturing and installation. The fewer components involved simplify the design of metering devices.

-

Improved Efficiency: The streamlined evaporation process often leads to improved thermodynamic efficiency. This translates directly into lower energy consumption and reduced operational costs. The consistent pressure and temperature profiles can optimize the entire cooling cycle.

-

Reduced Complexity of Control Systems: The constant boiling point simplifies the control algorithms required to manage the refrigeration system. Simple on-off switches, rather than sophisticated variable-speed drives, may be sufficient in some instances.

Key Properties and Characteristics of Azeotropic Refrigerant Mixtures

Azeotropic refrigerant mixtures possess several properties that set them apart from other refrigerants, making them attractive for various applications.

1. Constant Composition Throughout the Cycle

Unlike zeotropic mixtures, which change composition during evaporation and condensation, azeotropic mixtures maintain their original composition throughout the entire refrigeration cycle. This simplifies system design and maintenance, as there's no need to account for changing refrigerant properties. This consistency is a significant advantage, particularly in large-scale refrigeration systems where precise control is critical.

2. Improved Thermodynamic Performance

Due to their constant composition and boiling point, azeotropic mixtures often exhibit improved thermodynamic performance compared to their individual components. The optimized combination of refrigerants can lead to higher efficiency and lower energy consumption. This is particularly important in applications where energy costs are a major concern.

3. Enhanced Reliability and Stability

The consistent behavior of azeotropic mixtures enhances the reliability and stability of the refrigeration system. Fluctuations in temperature and pressure are minimized, reducing the risk of malfunctions and extending the lifespan of the equipment. This contributes to overall operational cost savings.

4. Reduced Environmental Impact (in certain cases)

Some azeotropic refrigerant mixtures are designed with a focus on reducing environmental impact. They may have lower global warming potentials (GWPs) and ozone depletion potentials (ODPs) compared to traditional refrigerants like R-22 or R-134a. The selection of components is crucial in creating environmentally friendly azeotropes.

5. Optimized for Specific Applications

Azeotropic refrigerant mixtures can be tailored for specific applications by carefully selecting the components. This allows for optimization of properties such as boiling point, critical temperature, and overall efficiency, making them suitable for various cooling demands, ranging from domestic refrigerators to large industrial chillers. Research and development continue to explore new azeotropic blends with enhanced characteristics.

Advantages and Disadvantages of Azeotropic Refrigerants

While azeotropic refrigerant mixtures offer numerous advantages, it's important to acknowledge their limitations.

Advantages:

- Simplified System Design: Their constant boiling point simplifies system design and maintenance.

- Improved Efficiency: Often leads to higher energy efficiency and lower operational costs.

- Enhanced Reliability: Minimizes temperature and pressure fluctuations, improving system reliability.

- Predictable Performance: Provides consistent and stable cooling performance throughout the cycle.

- Potential for Lower Environmental Impact: Some azeotropic blends have lower GWP and ODP than traditional refrigerants.

Disadvantages:

- Limited Availability: Compared to single-component refrigerants, the range of available azeotropic mixtures might be more limited. Research and development are constantly expanding the available options.

- Potential for Component Separation: While rare, under certain extreme conditions (like leakage or extremely high pressures), there might be a slight tendency for component separation. However, this is generally less significant compared to zeotropic blends.

- Specific Application Requirements: Choosing the right azeotropic mixture depends on the specific application and operating conditions.

Comparing Azeotropic and Zeotropic Refrigerant Mixtures

The key difference between azeotropic and zeotropic mixtures lies in their behavior during phase change. While azeotropic mixtures boil and condense at a constant temperature and composition, zeotropic mixtures exhibit a temperature glide (a range of boiling points). This temperature glide can lead to challenges in system design and control, as the composition and temperature vary throughout the cycle.

| Feature | Azeotropic Mixture | Zeotropic Mixture |

|---|---|---|

| Boiling Point | Constant | Variable (temperature glide) |

| Composition | Constant throughout cycle | Changes throughout cycle |

| System Design | Simpler | More complex |

| Efficiency | Potentially higher | Can be higher or lower depending on design |

| Control Systems | Simpler | More complex |

| Environmental Impact | Can be lower or higher depending on components | Can be lower or higher depending on components |

Azeotropic Refrigerants in Various Applications

Azeotropic mixtures are increasingly used across a wide range of applications:

- Domestic Refrigeration: In refrigerators and freezers, their reliability and efficiency contribute to energy savings and improved food preservation.

- Commercial Refrigeration: Supermarkets and restaurants benefit from the consistent cooling provided by azeotropic blends in large-scale refrigeration systems.

- Air Conditioning: In both residential and commercial air conditioning systems, azeotropic blends offer energy-efficient cooling.

- Industrial Processes: Many industrial processes require precise temperature control, making azeotropic refrigerants a suitable choice.

The Future of Azeotropic Refrigerant Mixtures

The ongoing research and development in refrigeration technology are continually pushing the boundaries of azeotropic refrigerant mixtures. Efforts are focused on:

- Developing new blends with lower GWPs and ODPs: Minimizing the environmental impact of refrigeration is a priority.

- Improving thermodynamic efficiency: Research focuses on achieving even higher energy efficiency.

- Expanding the range of available mixtures: Meeting diverse application requirements requires a broad range of azeotropic options.

- Exploring new applications: The versatility of azeotropic mixtures is leading to their adoption in increasingly diverse applications.

Conclusion: A Promising Path in Sustainable Refrigeration

Azeotropic refrigerant mixtures offer a compelling solution for efficient and sustainable refrigeration. Their unique properties, particularly their constant boiling point and composition, simplify system design, enhance reliability, and contribute to improved energy efficiency. While there are limitations, ongoing research and development continue to address these challenges, expanding the range of applications and enhancing the environmental profile of these versatile refrigerants. The future of cooling looks promising with the continued advancements and refinement of azeotropic refrigerant mixtures. Their unique characteristics solidify their position as a cornerstone of modern refrigeration technology, contributing to a more efficient and environmentally responsible future.

Latest Posts

Latest Posts

-

To Avoid A Spin While In A Skid You Should

Mar 28, 2025

-

The Designated Length Of A Ladder Is

Mar 28, 2025

-

What Are Two Advantages Of Selling Digital Products

Mar 28, 2025

-

One Shortfall Of The Act Is That

Mar 28, 2025

-

Identify The Parts Of The Fibrous Layer

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about What Is Unique About An Azeotropic Refrigerant Mixture . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.