Which Of The Following Machine Parts Always Require Guards

Breaking News Today

Mar 17, 2025 · 6 min read

Table of Contents

Which Machine Parts Always Require Guards? A Comprehensive Guide to Machine Safety

Machine guarding is paramount for workplace safety. Failing to adequately guard dangerous machine parts leads to preventable injuries, lost productivity, and hefty fines. This comprehensive guide delves into which machine parts always require guards, exploring the rationale behind these safety regulations and providing practical examples. Understanding these requirements is crucial for both employers and employees to create a safe and productive work environment.

The Importance of Machine Guarding: A Proactive Approach to Safety

Before diving into specific machine parts, it's vital to understand the overarching importance of machine guarding. The goal isn't simply to comply with regulations; it's to prevent accidents. Machines, by their nature, possess potential hazards. Moving parts, sharp edges, pinch points, and high temperatures are just a few examples of dangers inherent in industrial machinery.

Effective machine guarding acts as a physical barrier, preventing access to hazardous areas while the machine is operating. This barrier can take many forms, from simple guards to complex interlocked systems. The key is to ensure that the guard prevents contact with the hazardous part without impeding the machine's operation or creating new hazards.

Benefits of robust machine guarding programs include:

- Reduced workplace injuries: This is the primary benefit, saving employees from serious harm and potential long-term health issues.

- Improved worker morale and productivity: Employees feel safer and more confident when working with properly guarded machinery, leading to improved morale and efficiency.

- Lower insurance premiums: A strong safety record, including a comprehensive machine guarding program, often translates into lower workers' compensation insurance premiums.

- Compliance with regulations: Adhering to safety regulations avoids costly fines and legal repercussions.

- Enhanced company reputation: A commitment to safety demonstrates responsibility and professionalism, boosting the company's reputation.

Machine Parts that Always Require Guards: A Categorical Breakdown

While the specific requirements might vary depending on the jurisdiction and the nature of the machine, certain machine parts always necessitate guards due to their inherent dangers. These can be broadly categorized as follows:

1. Rotating Parts: A Major Source of Hazards

Rotating parts present significant dangers due to their potential for entanglement, striking, and crushing. These include:

- Rotating shafts: Any exposed rotating shaft, regardless of size, requires a guard. These guards should fully enclose the shaft, preventing contact with clothing or body parts. The guard material should be strong enough to withstand impacts and should be securely fastened to prevent dislodgement.

- Flywheels: Flywheels store significant kinetic energy, making them extremely hazardous if they fail or if someone comes into contact with them. Enclosures are crucial, typically incorporating interlocking safety switches to prevent operation when the guard is open.

- Pulley systems: Moving belts and pulleys pose a significant risk of entanglement and crushing. Guards should fully enclose the pulleys and belts, especially at pinch points where the belt contacts the pulley.

- Gears: Exposed gears are a major source of crushing and entanglement injuries. Guards should completely enclose the gear mesh, preventing access to the teeth.

- Spindles: Spindles, particularly those found in lathes and routers, require guards to prevent contact with rotating parts. These guards often incorporate safety features like adjustable shields and emergency stops.

Specific Examples:

- Lathes: The chuck, spindle, and rotating workpieces all require robust guards.

- Drill presses: The chuck and rotating drill bit require guards to prevent contact.

- Milling machines: The cutter and rotating workpieces necessitate thorough guarding.

2. Power Transmission Components: Hidden Dangers

Power transmission components often transfer substantial energy, creating hidden hazards. These include:

- Chains and sprockets: These components can cause crushing and entanglement injuries. Guards should fully enclose the chain and sprockets, with particular attention paid to pinch points.

- Belts and pulleys (reiteration): As mentioned earlier, these are inherently dangerous and necessitate full enclosure.

- Hydraulic and pneumatic cylinders: While not always rotating, these components can generate significant force, requiring guards to prevent crushing or impact injuries.

3. Cutting and Punching Mechanisms: Sharp and Potent Hazards

Machines with cutting or punching mechanisms demand meticulous guarding due to the obvious risk of severe lacerations. These include:

- Shears: The blades of shears require robust guards that prevent access to the cutting area while the machine is operating. These often incorporate light curtains or other safety interlocks.

- Press brakes: The ram and dies of press brakes pose a significant crushing and cutting hazard. Guards are crucial to prevent access during operation.

- Punch presses: The punch and die of punch presses are exceptionally dangerous. Guards are vital, often incorporating dual hand controls to prevent accidental activation.

- Circular saws: The rotating blade of a circular saw poses an obvious danger. Guards should cover the entire blade, with only a small portion exposed for cutting.

- Band saws: Similar to circular saws, band saws require guards to cover the blade, preventing contact.

4. Points of Operation: The Heart of the Hazard

The point of operation is where the work is actually performed – and often the most hazardous part of the machine. These areas always require guarding.

- Cutting, forming, and shaping operations: Any machine involved in these processes must have guards to protect workers from the moving parts and sharp edges.

- Assembly and disassembly operations: If these processes involve hazardous parts, suitable guarding must be in place.

Types of Machine Guards: A Diverse Arsenal of Protection

The type of guard employed depends on the specific hazard. Some common types include:

- Fixed guards: Permanently attached guards that completely enclose the hazardous area.

- Adjustable guards: Guards that can be adjusted to accommodate different workpiece sizes.

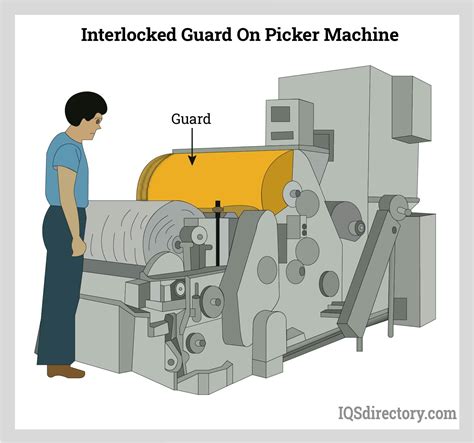

- Interlocked guards: Guards that prevent machine operation when opened.

- Two-hand controls: Require the operator to use both hands to activate the machine, preventing accidental operation.

- Light curtains: Non-contact sensors that detect when an object enters the hazardous area, stopping the machine.

Beyond Guards: Additional Safety Measures

While guarding is crucial, it's not the only safety measure. Additional precautions should always be implemented:

- Lockout/Tagout procedures: These procedures ensure that machines are completely de-energized before maintenance or repair.

- Training and education: Workers must be properly trained on safe operating procedures and the use of safety equipment.

- Regular inspections: Regular inspections of guards and other safety equipment are vital to ensure their effectiveness.

- Personal protective equipment (PPE): PPE such as safety glasses, hearing protection, and gloves should be worn as needed.

Conclusion: Prioritizing Safety Through Proactive Guarding

Machine guarding is not an optional extra; it's a fundamental aspect of workplace safety. By understanding which machine parts always require guards and implementing appropriate safety measures, employers can significantly reduce the risk of workplace accidents, creating a safer and more productive environment for their employees. Remember, the investment in safety is an investment in the well-being of your workforce and the success of your business. The cost of a single workplace accident far outweighs the cost of implementing and maintaining a robust machine guarding program. Prioritize safety; it's always the right decision.

Latest Posts

Latest Posts

-

Describe The Continuous Nature Of The Physical Fitness Concept

Mar 18, 2025

-

High Levels Of Cholesterol Can First Lead Directly To

Mar 18, 2025

-

True Or False Professional And Technical Communication Is Research Oriented

Mar 18, 2025

-

Which Best Describes The Terrorist Planning Cycle

Mar 18, 2025

-

Cdl Combination Test Questions And Answers Pdf

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about Which Of The Following Machine Parts Always Require Guards . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.