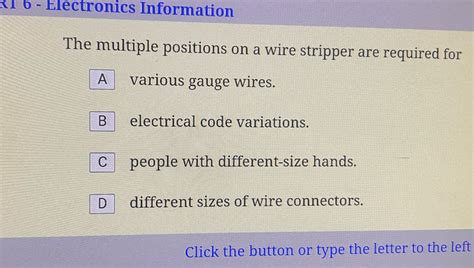

The Mutiple Position On A Wire Stripper Are Requried For

Breaking News Today

Mar 17, 2025 · 5 min read

Table of Contents

The Multiple Positions on a Wire Stripper: Why You Need Them All

Wire strippers are essential tools for electricians, technicians, and DIY enthusiasts alike. But have you ever stopped to consider why these seemingly simple tools often boast multiple stripping positions? It's not just about offering a single size; the various positions are meticulously designed to accommodate a wide range of wire gauges and insulation types, ensuring clean, efficient, and safe stripping every time. This article delves into the reasons behind the multiple positions found on wire strippers, explaining their function and importance in different scenarios.

Understanding Wire Gauge and Insulation Variety

Before diving into the intricacies of wire stripper positions, it's crucial to understand the diversity in wire types. Wire gauges, expressed in AWG (American Wire Gauge), range from extremely thin to incredibly thick. The smaller the AWG number, the thicker the wire. This difference in thickness directly impacts the amount of force and precision needed for stripping. Furthermore, insulation materials vary significantly in thickness and hardness. Some common materials include PVC (polyvinyl chloride), Teflon, silicone, and more. Each material requires a different approach to stripping to avoid damaging the wire underneath.

The Challenges of Inconsistent Stripping

Attempting to strip wires of varying gauges and insulation types using a single stripping position would likely lead to several problems:

- Wire damage: Applying too much pressure to a thin wire with a tool designed for thicker wires can easily nick or break the conductor. Conversely, using a position intended for thicker wires on thin wires might lead to incomplete stripping.

- Insulation damage: Applying incorrect pressure or using the wrong tool can lead to uneven stripping, leaving jagged edges or frayed insulation. This compromises the integrity of the connection, potentially leading to electrical faults or hazards.

- Inefficiency: Having to adjust pressure or use different tools for each wire significantly slows down the work process.

Deconstructing the Wire Stripper: A Position-by-Position Analysis

Most wire strippers feature multiple positions, each tailored for specific wire gauges and insulation types. While the exact number and size markings vary depending on the manufacturer and model, the underlying principles remain consistent. Let's examine some common positions:

Position 1: Thin Gauge Wires (e.g., 28-30 AWG)

This position typically features the smallest stripping hole or blade. It's designed for extremely fine wires used in delicate electronics, circuit boards, and other applications requiring high precision. The smaller opening ensures minimal pressure is applied, reducing the risk of damage to the delicate wire. Using a larger position would be catastrophic here, likely snapping the wire instantly.

Position 2: Small to Medium Gauge Wires (e.g., 22-26 AWG)

This position handles wires commonly found in smaller electronic devices, automotive applications, and some household wiring. It offers a balance between precision and stripping capacity. The slightly larger opening allows for greater efficiency while still maintaining control and reducing the chance of damage. This is a frequently used position for many common tasks.

Position 3: Medium Gauge Wires (e.g., 18-20 AWG)

This position caters to wires commonly used in household appliances, automotive lighting, and other moderately demanding applications. The increased size allows for effective stripping of thicker insulation without excessive force. Using a smaller position here would result in incomplete stripping, requiring significant extra effort and potentially damaging the wire.

Position 4: Large Gauge Wires (e.g., 10-16 AWG)

This position, if present, is for thicker wires often found in high-power applications like house wiring, large appliances, and industrial equipment. The increased size and strength of the stripping mechanism ensure efficient removal of thick insulation. Using a smaller position could lead to significant strain on the tool, potentially causing damage or injury.

Additional Positions: Specialized Functions

Some advanced wire strippers incorporate additional positions or features, further enhancing their versatility:

- Coaxial Cable Stripping: Specialized slots or blades are designed to strip the outer jacket of coaxial cables without damaging the inner conductor or dielectric.

- Wire Cutting: Many wire strippers incorporate a wire-cutting feature, providing an all-in-one tool for wire preparation. This eliminates the need for a separate wire cutter.

- Crimping: Some models combine wire stripping with crimping capabilities, allowing for both wire preparation and terminal connection in a single tool.

Choosing the Right Wire Stripper and Position

Selecting the appropriate wire stripper and understanding its various positions is vital for successful and safe work. Consider the following factors when making your choice:

- Wire Gauge Range: Ensure the stripper covers the entire range of wire gauges you'll be working with.

- Insulation Types: Check if the stripper is suitable for the types of insulation you’ll be dealing with.

- Ergonomics: A comfortable grip and easy-to-use mechanism will reduce hand fatigue and improve precision.

- Durability: A high-quality stripper will withstand regular use without losing its effectiveness.

Beyond the Basics: Advanced Stripping Techniques

While understanding the different positions is crucial, effective wire stripping also involves mastering several techniques:

- Proper Grip: Holding the wire stripper firmly but not excessively tight ensures consistent pressure and prevents slippage.

- Controlled Movement: Slowly and steadily rotate the wire stripper around the wire to achieve a clean and even strip.

- Practice: Regular practice will help you develop the skill and precision needed to use a wire stripper effectively.

Safety Considerations

Working with electricity necessitates utmost caution. Always follow these safety precautions:

- De-energize circuits: Before working on any wire, ensure the circuit is completely de-energized to prevent electrical shocks.

- Insulated Tools: Use insulated wire strippers to protect yourself from electrical hazards.

- Appropriate PPE: Wear appropriate personal protective equipment, such as safety glasses and gloves, to prevent injuries.

Conclusion: Mastering the Art of Wire Stripping

The multiple positions on a wire stripper are not merely superfluous features; they are integral components designed to ensure efficient, safe, and precise wire preparation across a wide range of applications. Understanding the function of each position is essential for professionals and DIY enthusiasts alike. By selecting the appropriate wire stripper and mastering the proper techniques, you can confidently tackle any wiring project with confidence and precision, leading to reliable and safe electrical connections. The investment in a quality tool and the time spent understanding its capabilities will pay dividends in the long run, ensuring both project success and personal safety. Remember to always prioritize safety and utilize the correct position for the specific wire gauge and insulation material to prevent damage and ensure optimal performance.

Latest Posts

Latest Posts

-

High Levels Of Cholesterol Can First Lead Directly To

Mar 18, 2025

-

True Or False Professional And Technical Communication Is Research Oriented

Mar 18, 2025

-

Which Best Describes The Terrorist Planning Cycle

Mar 18, 2025

-

Cdl Combination Test Questions And Answers Pdf

Mar 18, 2025

-

Life Insurance Exam Questions And Answers Pdf

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about The Mutiple Position On A Wire Stripper Are Requried For . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.