What Is Meant By The Term High Efficiency Purge Unit

Breaking News Today

Mar 27, 2025 · 6 min read

Table of Contents

What is Meant by the Term High Efficiency Purge Unit?

A high-efficiency purge unit (HEPU) is a specialized piece of equipment designed to efficiently remove contaminants from a process stream or system. Unlike simpler purge systems, HEPUs employ advanced technologies and meticulous engineering to achieve significantly higher levels of contaminant removal, resulting in improved product quality, enhanced safety, and reduced environmental impact. This article will delve into the intricacies of HEPUs, exploring their functionalities, applications, key components, and the advantages they offer compared to traditional purge systems.

Understanding the Concept of Purging

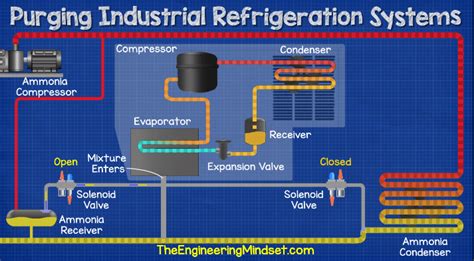

Before diving into the specifics of high-efficiency purge units, it's essential to understand the broader concept of purging. Purging, in an industrial context, refers to the process of removing unwanted substances from a system or pipeline. These unwanted substances can include:

- Residuals: Leftover materials from previous processes.

- Contaminants: Unwanted substances introduced during operation.

- Gases: Air, vapors, or other gases that might compromise the integrity of the process.

- Liquids: Excess liquids that need to be removed before a new process begins.

The goal of purging is to ensure the system is clean, dry, and free from contaminants that could affect the quality, consistency, or safety of subsequent operations. This is crucial in various industries, including pharmaceuticals, chemicals, food processing, and semiconductor manufacturing.

The Advantages of High-Efficiency Purge Units

HEPU systems offer several significant advantages over traditional purging methods, leading to their increasing adoption across various industries:

- Superior Contaminant Removal: HEPUs excel at removing even trace amounts of contaminants, leading to significantly higher purity levels in the process stream. This is vital in applications where stringent purity standards are paramount.

- Reduced Waste: By efficiently removing contaminants, HEPUs minimize waste generation, contributing to environmental sustainability and reducing disposal costs.

- Improved Product Quality: The high level of cleanliness achieved through HEPU use directly translates to higher-quality products with improved consistency and performance.

- Enhanced Safety: Removing flammable or hazardous materials effectively enhances safety in the workplace, reducing the risk of explosions, fires, or exposure to harmful substances.

- Increased Efficiency: HEPU systems are often designed for optimized performance, leading to faster purging cycles and reduced downtime, thus improving overall productivity.

- Reduced Operational Costs: While the initial investment in a HEPU might be higher, the long-term savings from reduced waste, improved product quality, and enhanced safety often outweigh the initial cost.

Key Components and Functionalities of a HEPU

A typical HEPU comprises several key components working in concert to achieve high-efficiency purging:

- High-Efficiency Filters: These are the heart of the HEPU, typically employing advanced filtration technologies such as HEPA (High-Efficiency Particulate Air) filters or ULPA (Ultra-Low Penetration Air) filters. These filters are capable of removing particles down to sub-micron sizes, ensuring exceptional contaminant removal. The specific filter media chosen depends heavily on the nature of the contaminants being removed.

- Vacuum System: A robust vacuum system is crucial for drawing the contaminants through the filtration system. The vacuum level and capacity must be sufficient to handle the volume and viscosity of the process stream.

- Flow Control System: Precise control over the flow rate is essential to optimize the purging process and prevent damage to sensitive equipment. This system ensures that the contaminants are drawn through the filters at an appropriate rate.

- Pressure Monitoring System: Monitoring the pressure drop across the filters is critical for determining their efficiency and identifying when they need to be replaced or cleaned. Sudden pressure spikes could indicate blockages or other issues.

- Purge Gas Supply: In many applications, a clean purge gas (e.g., nitrogen, argon) is used to displace the contaminants and carry them towards the filtration system. The purity and flow rate of the purge gas are carefully controlled.

- Monitoring and Control System: A sophisticated monitoring and control system is essential for overseeing the entire purging process, providing real-time data on pressure, flow rate, and filter efficiency. This allows for proactive adjustments and minimizes downtime.

Applications of High-Efficiency Purge Units

HEPU systems find applications in a wide range of industries, wherever high purity and cleanliness are critical:

- Pharmaceutical Industry: HEPUs are essential for maintaining sterility and preventing contamination in pharmaceutical manufacturing processes. They are used to purge pipelines, vessels, and other equipment before and after production runs.

- Chemical Industry: In the chemical industry, HEPUs are used to remove residual chemicals, prevent cross-contamination, and ensure the safety of personnel and equipment.

- Semiconductor Manufacturing: The extremely high purity requirements of semiconductor manufacturing necessitate the use of HEPUs to remove even trace amounts of contaminants that could affect the performance of microchips.

- Food and Beverage Industry: HEPU systems are used to maintain hygiene and prevent contamination in food and beverage processing, ensuring the safety and quality of products.

- Aerospace Industry: In aerospace applications, where even minute particles can be detrimental, HEPUs are critical for maintaining cleanliness and preventing contamination during the manufacturing of sensitive components.

- Medical Device Manufacturing: Similar to pharmaceutical manufacturing, the stringent cleanliness requirements for medical devices necessitate the use of HEPUs to prevent contamination and ensure product safety.

Choosing the Right HEPU

Selecting the appropriate HEPU for a specific application requires careful consideration of several factors:

- Contaminant Type and Concentration: The type and concentration of contaminants to be removed will dictate the necessary filtration technology and system capacity.

- Process Stream Characteristics: The volume, pressure, temperature, and viscosity of the process stream will influence the design and specifications of the HEPU.

- Purity Requirements: The required level of purity will determine the choice of filter media and the overall system design.

- Budgetary Constraints: The initial investment cost and ongoing operational costs should be carefully evaluated.

- Space Limitations: The available space for the HEPU installation must be considered.

- Maintenance Requirements: The ease of maintenance and the frequency of filter changes should be factored into the decision.

Comparing HEPUs to Traditional Purge Systems

Traditional purge systems often rely on simpler methods such as pressurized air or liquid flushing, which may not be sufficient for removing trace contaminants or achieving the high purity levels required in many applications. HEPU systems offer several key advantages:

| Feature | Traditional Purge System | High-Efficiency Purge Unit (HEPU) |

|---|---|---|

| Contaminant Removal Efficiency | Low | Very High |

| Purity Levels Achieved | Low | Very High |

| Waste Generation | High | Low |

| Cost | Low Initial Cost, High Operational Cost | High Initial Cost, Low Operational Cost |

| Complexity | Simple | Complex |

| Maintenance | Relatively Simple | More Complex |

Future Trends in High-Efficiency Purge Unit Technology

The field of HEPU technology is constantly evolving, with ongoing advancements focusing on:

- Improved Filtration Technologies: The development of even more efficient filter media with higher dust-holding capacity and longer service life.

- Automation and Control: Increased automation and sophisticated control systems for enhanced efficiency and reduced operator intervention.

- Miniaturization: The development of smaller and more compact HEPUs for applications with space constraints.

- Integration with other systems: Seamless integration with other process equipment for improved overall efficiency.

- Sustainability: The development of more environmentally friendly HEPUs with reduced energy consumption and waste generation.

In conclusion, high-efficiency purge units represent a significant advancement in purging technology, offering superior contaminant removal, enhanced safety, improved product quality, and reduced environmental impact. Their application across various industries underscores their critical role in ensuring high purity and cleanliness in a diverse range of processes. As technology continues to advance, HEPUs are poised to play an even greater role in ensuring the quality, safety, and sustainability of industrial processes worldwide.

Latest Posts

Latest Posts

-

Suggested Initial Dose Of Epinephrine Nrp 8th Edition

Mar 30, 2025

-

When Is The Best Time To Check For Identification

Mar 30, 2025

-

The Things They Carried Summary By Chapter

Mar 30, 2025

-

Explain Why Water Is A Polar Molecule

Mar 30, 2025

-

Post World War I Recovery Crash Course European History

Mar 30, 2025

Related Post

Thank you for visiting our website which covers about What Is Meant By The Term High Efficiency Purge Unit . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.